UV Disinfection FOR MUNICIPAL Wastewater

Wastewater is the gateway to environmental pollution from any human activity. In the past, the most common method to inactivate dangerous microorganisms found in effluent and discharge was chlorine in gas or fluid form. In recent years however, disadvantages of the method have been revealed: dangerous by-product formation (such as THMs and HAAs with others still unknown), high costs due to increasing requirements in the de-chlorination step, the administration that follows, and the danger of handling and storing toxic chemicals.

All of these hindrances has made UV disinfection the preferred method, proven to be effective for secondary and tertiary treatments. It also offers a significantly lower environmental impact, design footprint, and costs. Additionally, unlike chlorine, it is effective against Cryptosporidium and Giardia.

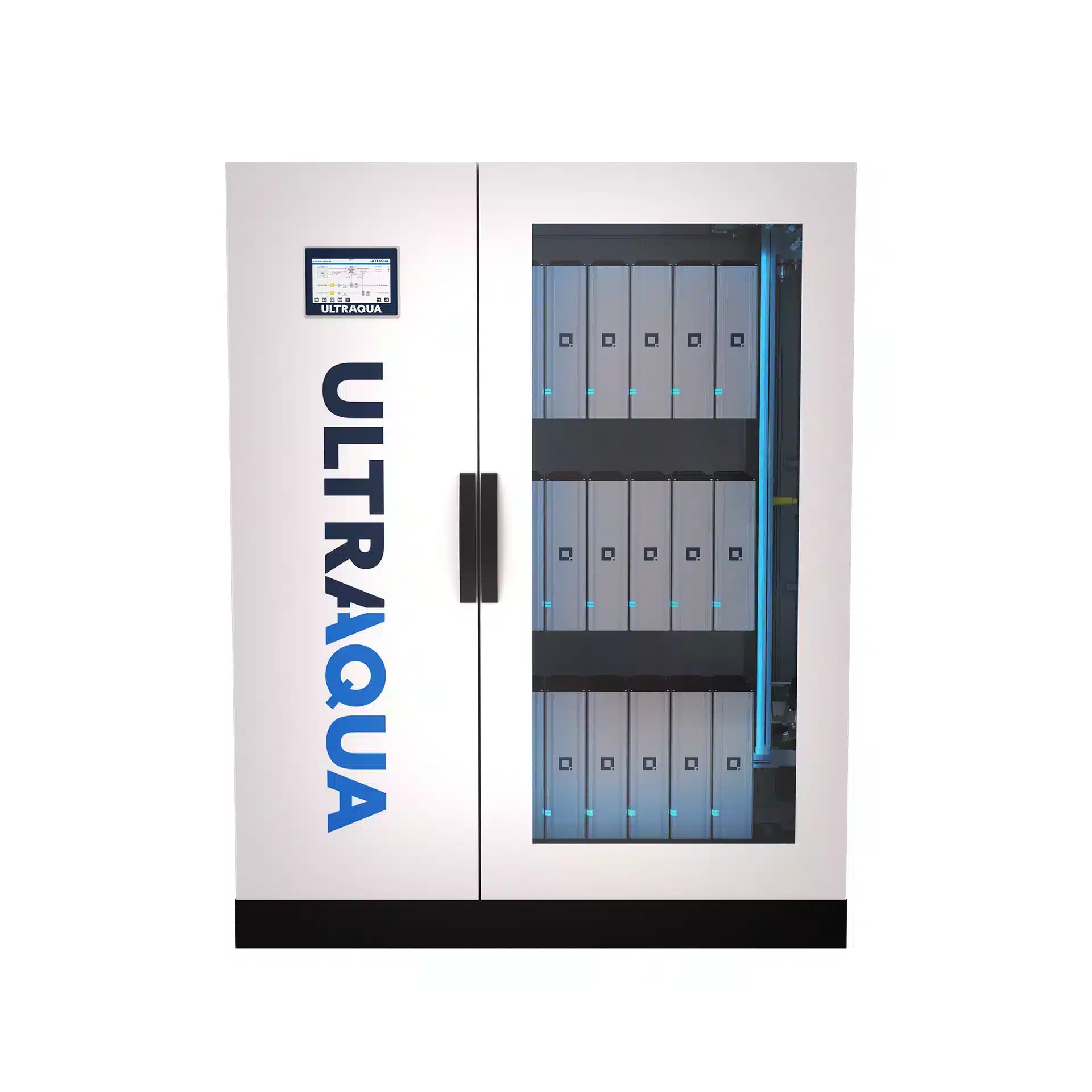

A wide selection of ULTRAAQUA UV closed vessel and open channel UV systems excel in energy and disinfection efficiency, overall cost optimization, advanced scalability and customization, ease of operation, and maintenance. Today, ULTRAAQUA UV units disinfect more than 54 856 m3/h of wastewater globally. With R&D as the company’s backbone, our customers are ensured the latest UV technology available in the market. ULTRAAQUA UV systems can also be easily integrated for direct and in-direct water re-use (aka. reclamation), Total Organic Carbon (TOC) reduction, and Advanced Oxidation Process (AOP) applications.

UV DISINFECTION SYSTEMS FOR MUNICIPAL WASTEWATER TREATMENT

FREQUENTLY ASKED QUESTIONS (FAQ)

Find frequently asked questions regarding UV disinfection for this application by clicking on a question below.

What are the advantages of using UV disinfection for municipal wastewater?

UV disinfection offers several advantages for treating municipal wastewater. It is a safe and effective method that avoids the use of hazardous chemicals, eliminating the risk of toxic by-products such as trihalomethanes (THMs) and haloacetic acids (HAAs). UV disinfection is also effective against chlorine-resistant pathogens like Cryptosporidium and Giardia, ensuring a higher level of public health protection.

How does UV systems contribute to the sustainability of WWTP's?

UV disinfection contributes to sustainability by reducing the environmental impact of wastewater treatment. It does not generate harmful by-products that can be released into the environment. Additionally, UV systems often have a smaller design footprint and lower operational costs compared to chemical disinfection methods, making them a more eco-friendly and cost-effective solution.

Are UV systems capable of handling the high flow rates of WWTP's?

The UV systems from ULTRAAQUA UV are scalable to handle virtually any flow rates seen in municipal wastewater treatment facilities. They are engineered for both secondary and tertiary treatment stages, offering scalability and customization to meet the specific needs of each facility. This ensures that all treated water meets the defined safety standards before being discharged or reclaimed.

How does UV disinfection impact the operational costs of WWTP's?

UV disinfection can positively impact the operational costs of wastewater treatment plants. While the initial investment in UV equipment may be higher compared to some traditional methods, the overall operational and maintenance costs are generally lower. UV systems have fewer moving parts, require less space, and do not need the ongoing purchase and handling of chemicals, which can lead to significant cost savings over time.

Are UV systems effective against antibiotic-resistant bacteria in wastewater?

Yes, UV disinfection is effective against antibiotic-resistant bacteria. The UV light inactivates bacteria by damaging their DNA, making it an effective solution for treating water that contains antibiotic-resistant strains. This is particularly important in municipal wastewater treatment, where such bacteria can be prevalent.

Can UV systems be integrated into existing WWTP's without major modifications?

Most of the time, UV systems can be integrated into existing wastewater treatment plants with minimal modifications. UV systems are designed to be compact and can be installed in various configurations to suit the existing infrastructure. This flexibility allows for a relatively straightforward integration process, making UV a viable option for upgrading and improving existing wastewater treatment facilities.