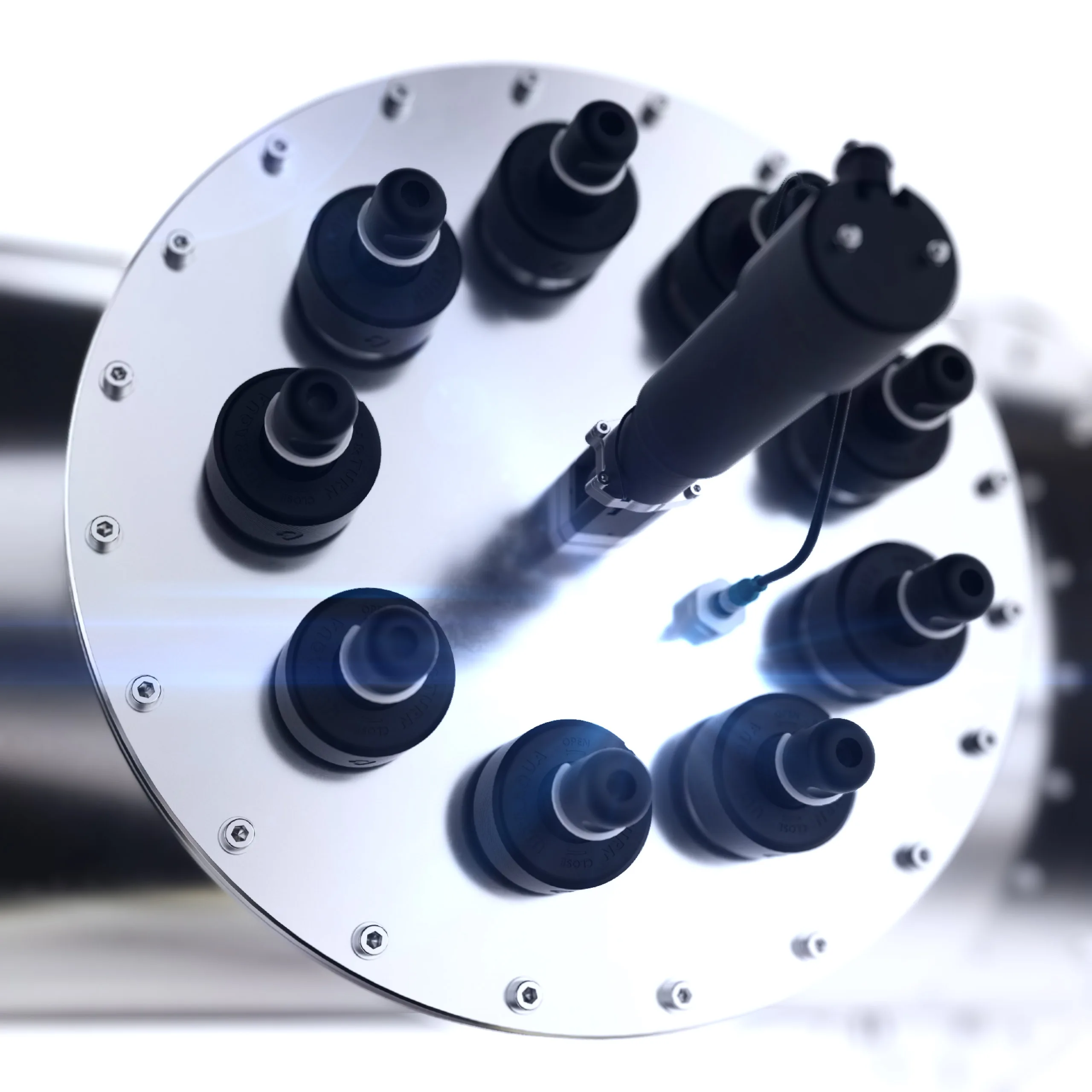

ELECTROPOLISHED STAINLESS-STEEL AISI 316L REACTOR

MARKET LEADING ENERGY EFFICIENCY

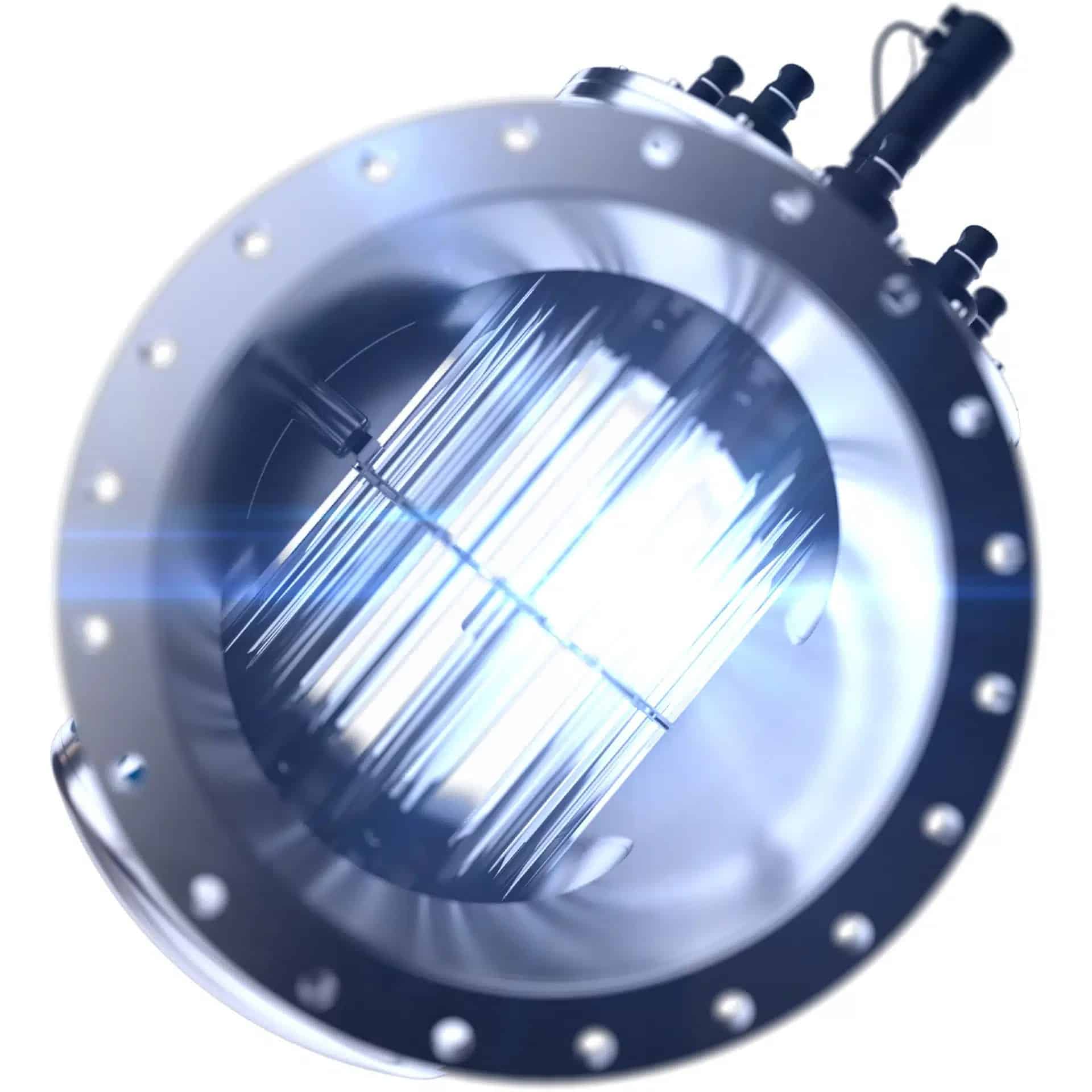

CFD-OPTIMIZED LAMP POSITIONING

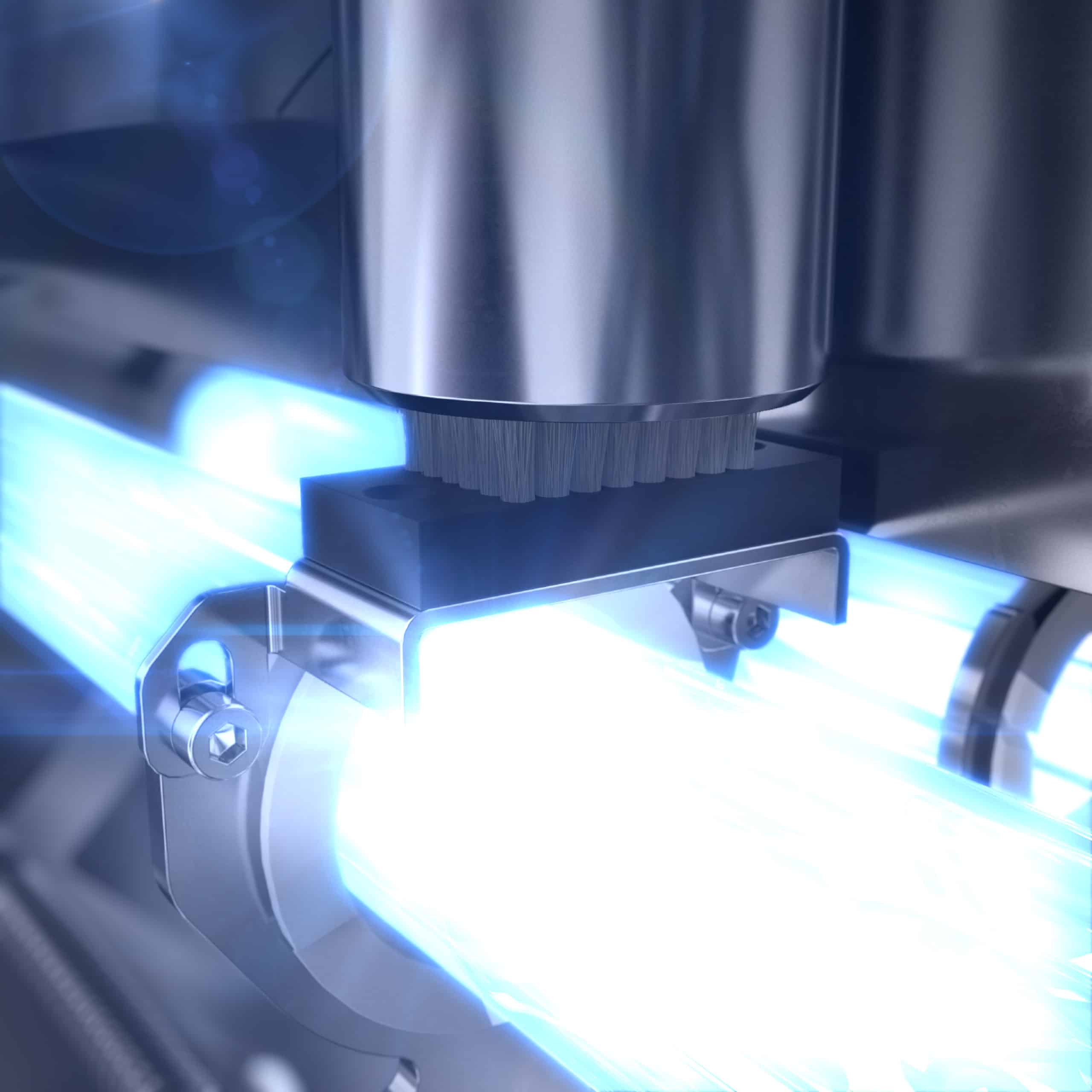

AUTOMATED ULTRAWIPER QUARTZ CLEANING

CLEANING WITH TAILORED BRUSH HEADS

HORIZONTAL OR VERTICAL MOUNTING

EASILY INTEGRATED INTO COMPLEX ENVIRONMENTS

PRODUCT DESCRIPTION

ULTRATRON ADVANCED OXIDATION PROCESS UV SYSTEMS

Advanced Oxidation Processes (AOP) is a common name for the chemical/photochemical reactions that generate OH-radicals in the water, with the purpose of degrading persistent and toxic chemical compounds. Typical examples of UV based advanced oxidation processes are UV/Hydrogen Peroxide, UV/Chlorine, UV/Ozone, UV/Persulfate, and Vacuum-UV.

OH-radicals react fast with most organic compounds in second-order reactions, resulting in complex radical chain reactions that often lead to mineralization of the organic compounds with CO2 and water as end products. AOP is frequently employed as a final polishing step in many water treatment applications, to provide combined disinfection and removal of trace organic compounds to very low levels, thus ensuring water of very high purity.

ULTRAAQUA provides the most efficient and customized AOP solutions using advanced integrated CFD, UV fluence field, and radical chemistry process models with the purpose of calculating and optimizing the space-dependent OH-radical concentration and prediction of the target compound degradation.

The result is a selection of reaction system, lamp type, and optimal reactor design that ensures an efficient treatment process, taking into account the physicochemical characteristics of the water matrix and target compounds. With highly complex water matrices, empirical target compound degradation can be obtained experimentally in ULTRAAQUA’s high-quality research laboratory.

KEY HIGHLIGHTS

- Guaranteed target compound(s) removal

- Highest energy efficiency in AOP solution design

- Optimal chemical utilization through CFD and UV fluence field optimized hydraulic conditions

- Experimental validation of process efficiency as input to design

- Automated ULTRAWIPER quartz sleeve wiping technology – Stable disinfection process

- High-grade electropolished stainless steel AISI 316L construction – Up to 30% energy savings with internal reflection