ELECTROPOLISHED STAINLESS-STEEL AISI 316L REACTOR

EASILY INTEGRATED INTO COMPLEX ENVIRONMENTS

HORIZONTAL OR VERTICAL MOUNTING

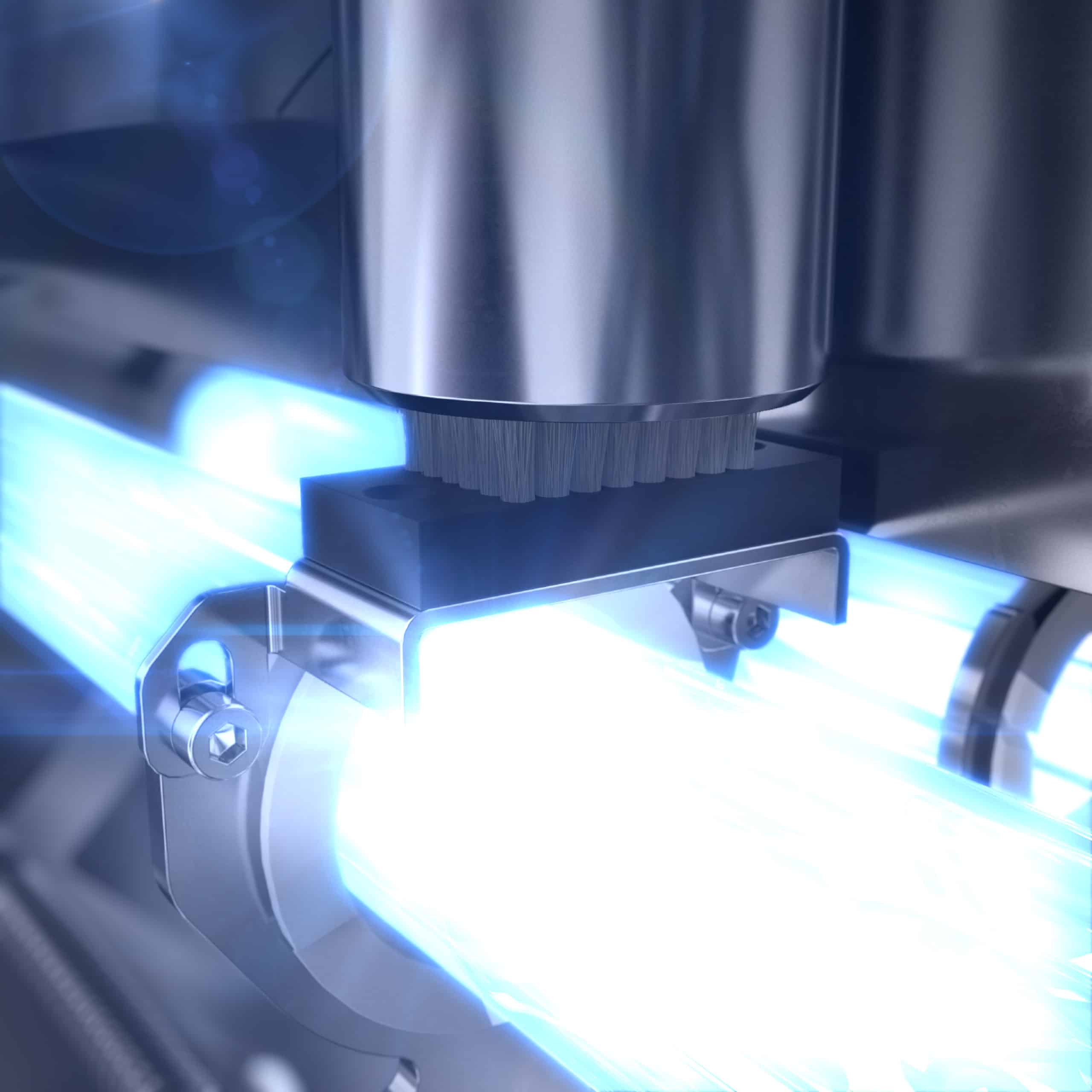

AUTOMATED ULTRAWIPER QUARTZ CLEANING

CFD-OPTIMIZED LAMP POSITIONING

CLEANING WITH TAILORED BRUSH HEADS

MARKET LEADING ENERGY EFFICIENCY

PRODUCT DESCRIPTION

ULTRATRON UV DISINFECTION SYSTEMS

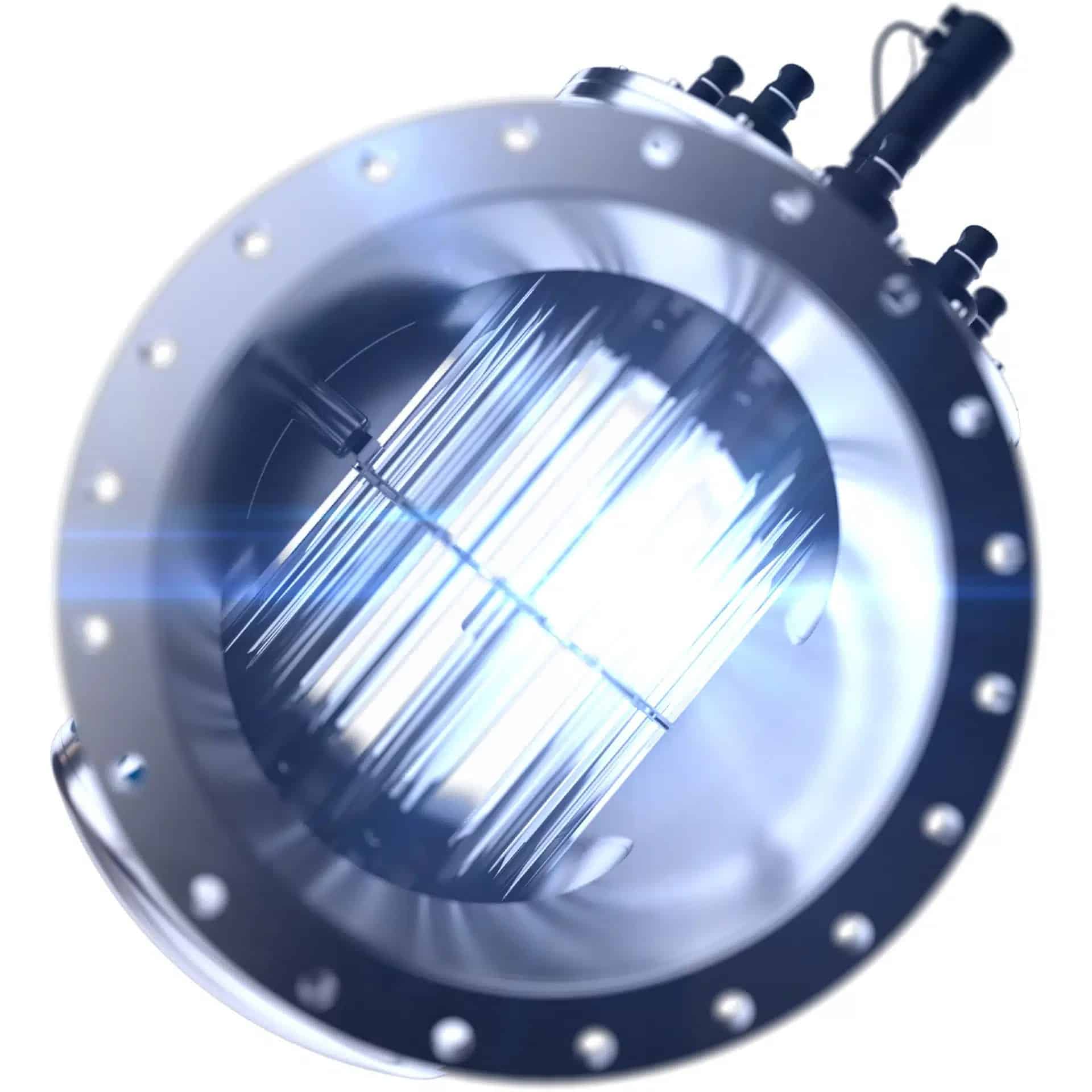

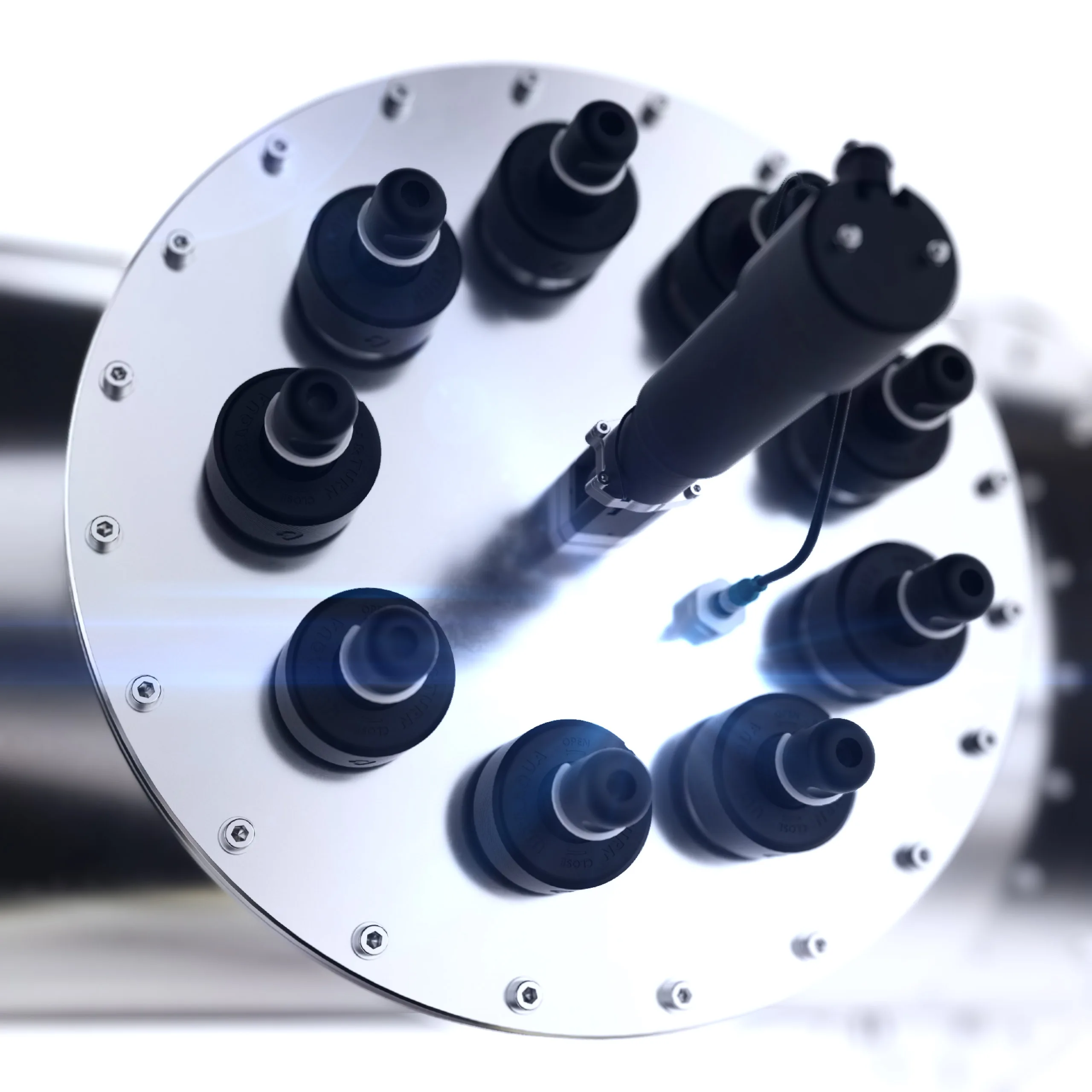

The ULTRATRON series is based on the latest Medium-Pressure High Intensity (MPHI) lamp technology, optimized for high flow applications where a small footprint is essential and high-power densities are required. The integrated ULTRATHERM Medium Pressure High Intensity (MPHI) lamps offers market leading lamp efficiency in UV-C output density with 9 000 hours guaranteed lamp lifetime.

The ULTRATRON series is easily integrated into the most complex environments, both vertically and horizontally. The flanged connection is suitable into existing infrastructure, which makes it ideal for retrofitting at almost any scale. The compact reactor and CFD optimized lamp placing allows maximum hydraulic efficiency throughout the entire UVT range with minimum head loss.

The internal reflection of the electropolished system provides efficiency improvements of up to 30% at high UVT’s, making the ULTRATRON an ideal product range for general disinfection as well as for advanced photocatalytic applications. Additionally, the lamps include a stabilizing design to ensure that the system is protected against any residual vibrations or shocks.

KEY HIGHLIGHTS

- The smallest footprint for the highest flow rate possible

- Maximum hydraulics efficiency / Minimum head loss optimization

- Double security against overheating

- Single or multiple lamp configuration

- 9000h ULTRATHERM UV lamp lifetime

- ULTRAWIPER – automated quartz sleeve wiping system

- The quickest maintenance downtime achieved – no tools needed for lamp replacement

- Corrosion-resistant GFRP, carbon steel or stainless-steel control cabinets