UV SYSTEMS FOR WELLBOATS

The role of wellboats in the aquaculture industry has been crucial as it serves as a bridge between on-shore and off-shore aquaculture facilities. However, their versatility comes with several challenges, the biggest one ensuring biosecurity for both process and discharge water. This has led the veterinarians and farmers to determine that the most optimal solution is the closed system wellboat – due to safety and increasingly stricter regulations for disease control in inside and outside environments. One of the most affected areas is the treatment of intake water, which then becomes a preference. This is due to multiple bacteria, viruses and sea lice being released back into the marine environment during the discharge stage of the transport water.

Even though there are designated locations for this process – there is no method to ensure that it doesn’t cross-contaminate. It also possesses a threat to other wellboats intaking the new water in potentially nearby areas. The challenge is that after treating intake water, dangerous microorganisms can still enter the closed system through “dead volume” water that cannot be fully reached during standard cleaning operation such as pumps, pipes, or complex technical equipment. The most difficult, yet ultimate solution is ensuring that the intake and process water passing through piping and the entire system has the highest possible standard or has just enough microorganisms to develop or sustain the immunity of the fish transported.

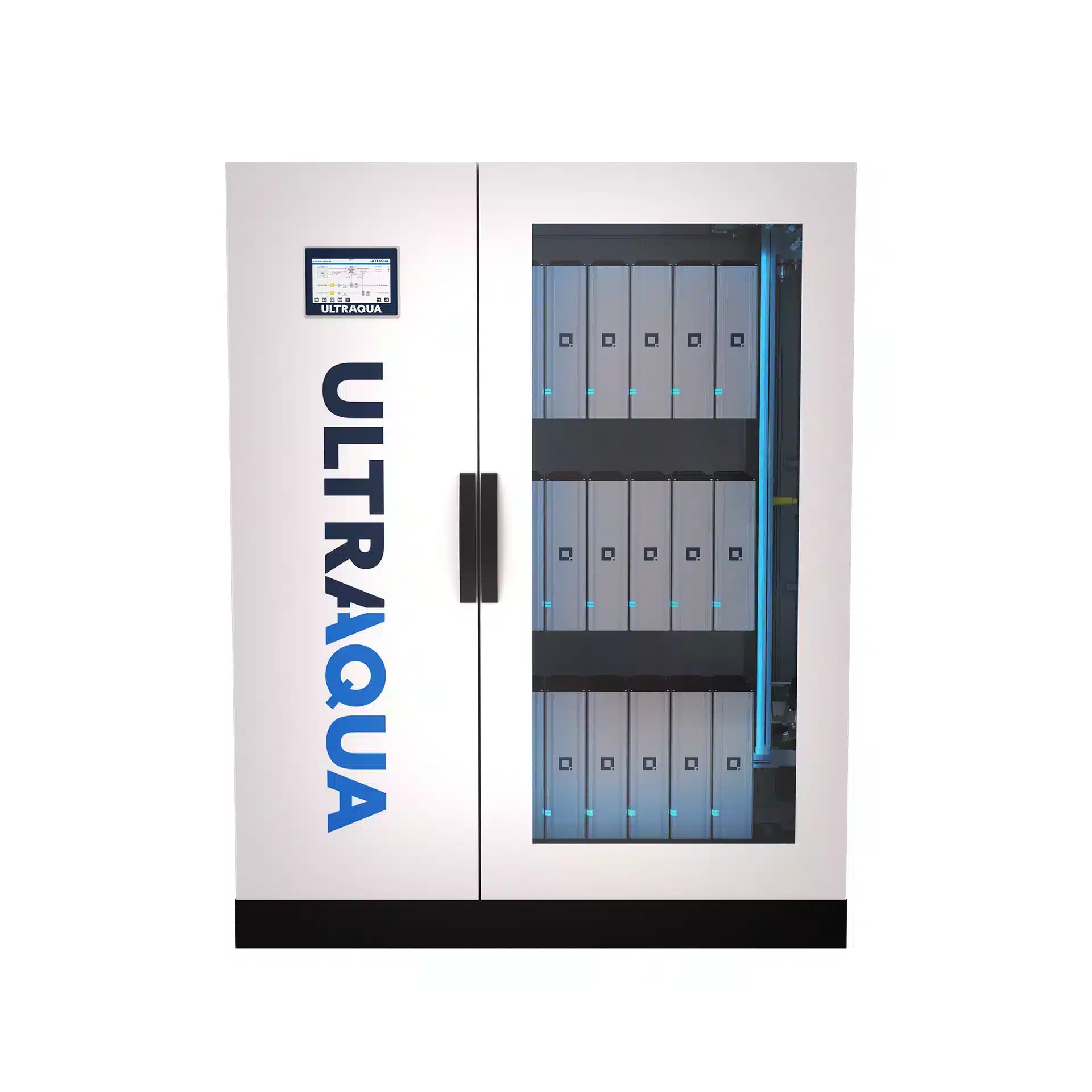

UV disinfection has been widely implemented in the wellboat industry. Mainly due to not influencing the key water properties in the aquaculture industry – temperature and pH or oxygen levels and effectiveness on the common bacterial and viral diseases. It is also easily implemented in different steps of the wellboat whether it is water inlet, outlet, or process areas. Finally, it offers its users the most optimal APEX and OPEX compared to other alternatives as well as having the lowest footprint which is essential in smaller spaces.

FREQUENTLY ASKED QUESTIONS (FAQ)

Find frequently asked questions regarding UV disinfection for this application by clicking on a question below.

Why are UV systems beneficial for disinfection in wellboat operations?

UV disinfection plays a vital role in wellboat operations for maintaining the health and welfare of the fish during transport. UV systems effectively neutralize harmful pathogens and parasites in the water, reducing the risk of disease outbreaks to ensure that the fish remain healthy throughout the journey.

How does UV treatment benefit the overall quality of water in wellboats?

UV treatment significantly improves the water quality in wellboats by eliminating microorganisms that can degrade water conditions. This leads to a healthier environment for the fish, reducing stress and mortality rates during transport.

Is UV disinfection a cost-effective water treatment method?

UV disinfection is a cost-effective solution for wellboats, as it helps in reducing losses due to disease and contributes to the overall health and overall quality of the fish, leading to better market value.

How does UV treatment contribute to sustainable aquaculture practices in wellboats?

UV treatment contributes to sustainable aquaculture practices by providing a chemical-free method of maintaining water quality. This approach aligns with environmental conservation efforts and ensures the well-being of the fish, supporting sustainable aquaculture practices.