UV DISINFECTION FOR GEOSMIN MIB MITIGATION

Geosmin and Methyl-Isoborneol (MIB) are naturally occurring compounds commonly found in fish in RAS (Recirculating Aquaculture Systems) production. Both substances accumulate in the fat tissue of the fish and lead to a muddy earthy taste of the fish. Every year this leads to high economic losses for the aquaculture industry caused by prolonged production times due to the need to off-flavor the fish in purge tanks and further by the rejection of produce by the fish refining companies.

As of today, the usual method to remove geosmin from the fish is by placing them into large high purity water tanks that are rich in oxygen. However, this is a relatively costly method to ensure proper removal, as large quantities of pure water are required. ULTRAAQUA UV research department has first-hand experience in solving and documenting geosmin control.

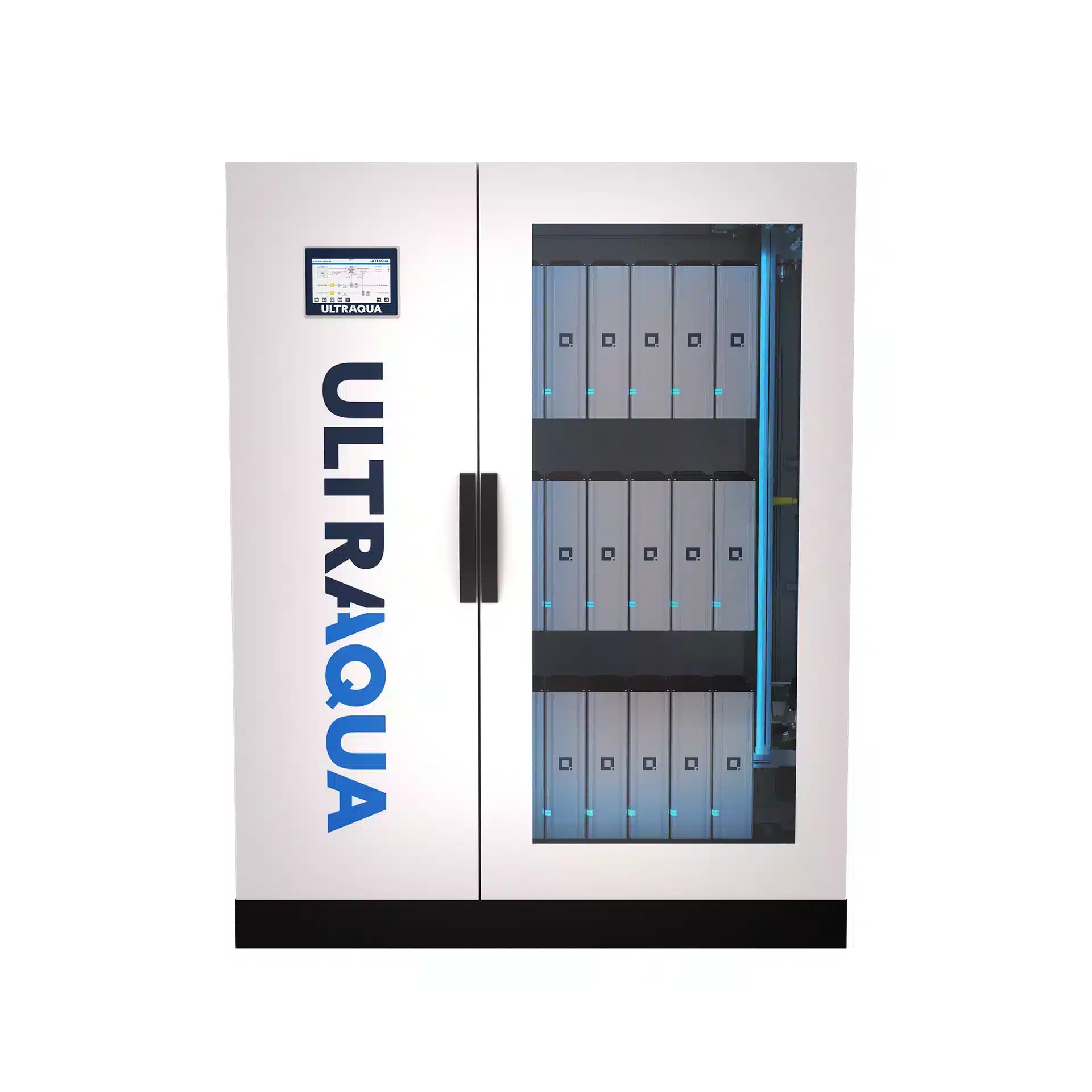

The most optimal strategy in removing geosmin is to avoid or minimize the concentration of geosmin in the culture tanks and thus minimizing the need for off-flavoring in the purge tanks further on. ULTRAAQUA UV experts will assist in optimizing plant layout and management strategies to reduce geosmin formation. In addition, ULTRAAQUA UV offers equipment to remove accumulated geosmin. The optimal solution typically varies from site to site depending on local characteristics.

Often the optimal solution involves ULTRAAQUA AOP systems for combined chemical oxidation and photolysis breakdown. It is important to note that each case is sensitive and different requiring close investigation due to RAS intenseness, the multiple processes involved, and variation in overall farm management.

FREQUENTLY ASKED QUESTIONS (FAQ)

Find frequently asked questions regarding UV disinfection for this application by clicking on a question below.

What is Geosmin and MIB, and why are they a concern in aquaculture?

Geosmin and Methyl-Isoborneol (MIB) are naturally occurring compounds often found in fish from Recirculating Aquaculture Systems (RAS). The compounds accumulate in the fat tissue of fish, leading to an earthy, muddy taste. This not only affects the quality of the fish but also leads to economic losses due to extended production times and potential rejection by fish refining companies.

What is the role of UV disinfection in mitigating Geosmin and MIB in water?

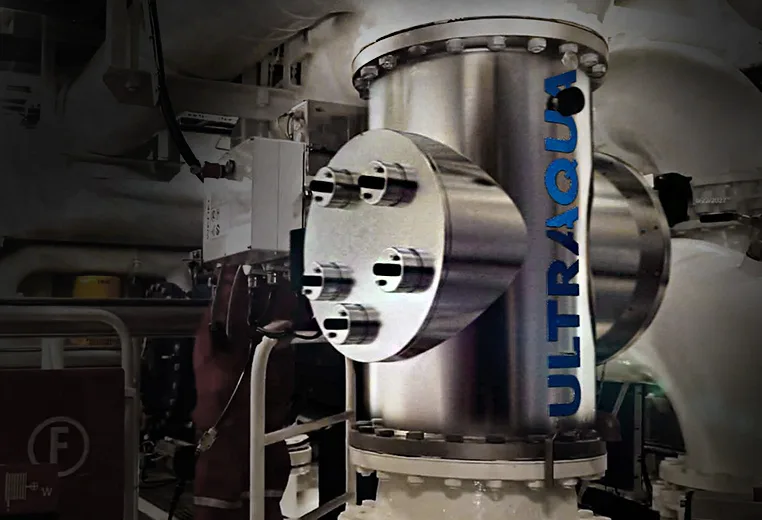

UV disinfection can play a crucial role in mitigating Geosmin and MIB (2-Methylisoborneol) in water, which are compounds responsible for earthy and musty odors. UV treatment is capable of breaking down these compounds, improving the water’s taste and odor.

What are the traditional methods for removing Geosmin and MIB from fish?

Traditionally, fish are placed in large tanks of high-purity, oxygen-rich water to remove Geosmin and MIB. While effective, this method is costly and requires large quantities of pure water, making it a less feasible option for many aquaculture operations.

How do ULTRAAQUA AOP systems contribute to the mitigation of Geosmin and MIB?

The AOP systems from ULTRAAQUA use a combination of chemical oxidation and photolysis to effectively break down Geosmin and MIB. This advanced treatment method is particularly beneficial in handling the complex nature of these compounds in RAS facilities.