UV DISINFECTION for Shrimp and Prawn Farming

The shrimp farming industry experienced exponential growth in the past few decades. Especially in regions with the ideal conditions for the Penaeus Monodon (Giant tiger prawn) and Litopenaeus Vannamei (whiteleg shrimp) rearing – warm and saline water environments. The increasing demand and production volumes have also led to increased stocking densities and growth in fatal diseases due to the lack of effectiveness concerning vaccinations and nutrient-filled diets.

Adding more nutrients to the diet usually creates grounds for further contamination. All of this leads to the conclusion that the most successful disease control method is ensuring water biosecurity used in the production process. Notably for the hatcheries and nurseries as proper rearing of post-larval and juvenile shrimp leads to a more resilient grow-out stage and higher shrimp survival rates further down the line.

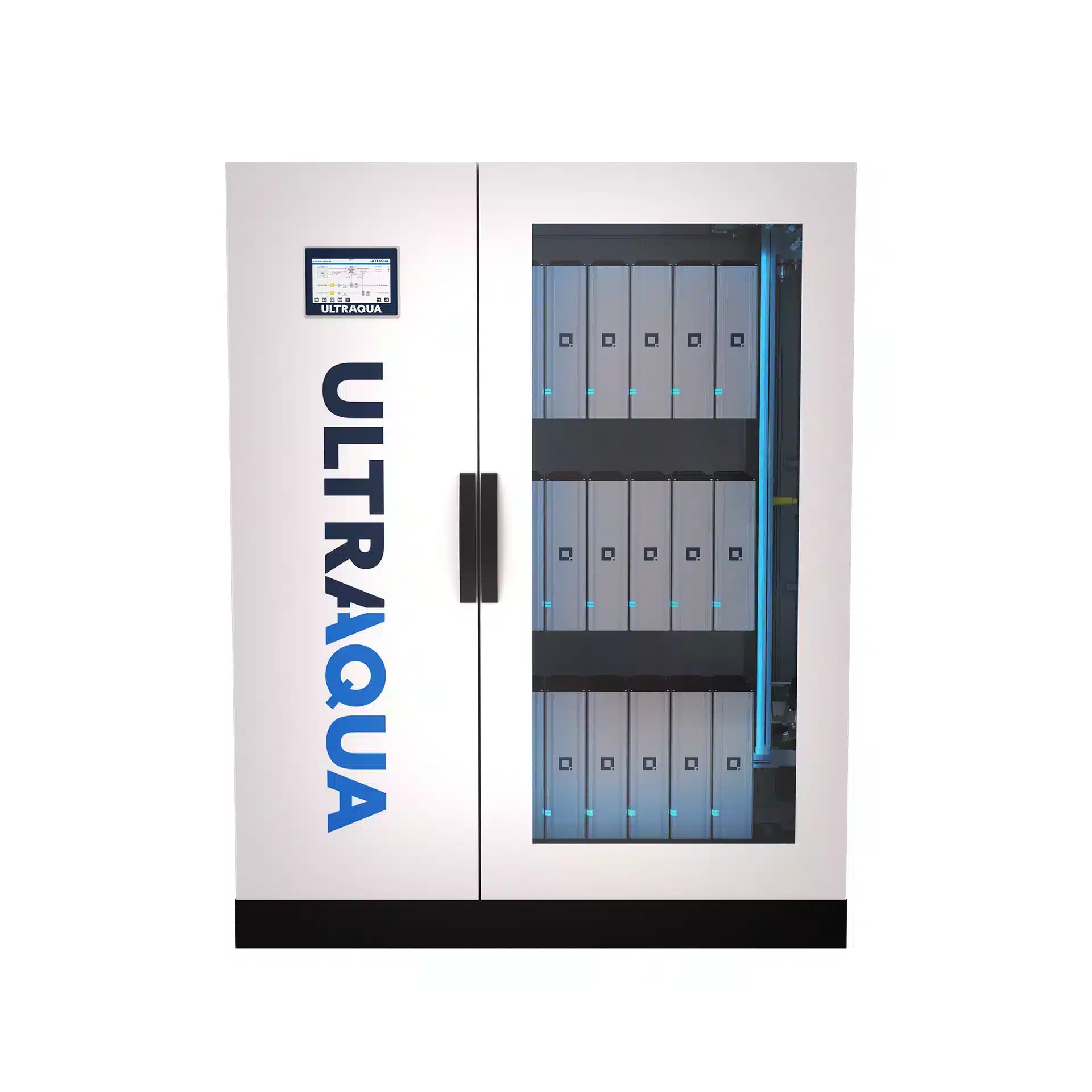

ULTRAAQUA UV systems are well-rounded and efficient water disinfection solution for different stages of shrimp farming – hatcheries, nurseries, or intensive grow-out facilities. Since it is a physical process rather than chemical, it does not create reactive residues and does not alter water properties, while efficiently inactivating all common shrimp diseases such as White Spot Syndrome (WSSV), Vibrio, EMS, and Mortality Syndrome (EHP).

ULTRAAQUA UV is the only UV manufacturer that has specifically designed a UV system series for the shrimp industry made of non-corrosive polypropylene material which is known for its longevity properties in saltwater environments. Ideal for intake, process, and discharge water, ULTRAAQUA UV systems have also led the shrimp farmers to experience better feed conversion ratios, a significant reduction of antibiotic use, an improved survival rate across all steps of shrimp rearing. The combination of all these advantages yields a superior end-product. ULTRAAQUA UV systems are also effective in chlorine and ozone destruction applications to prevent potential negative impacts on the cultured species.

FREQUENTLY ASKED QUESTIONS (FAQ)

Find frequently asked questions regarding UV disinfection for this application by clicking on a question below.

How does UV disinfection support the health of shrimp during the farming process?

UV disinfection is a critical component in maintaining water biosecurity at all stages of shrimp farming, from hatcheries to nurseries and grow-out facilities. It effectively inactivates common shrimp diseases such as White Spot Syndrome (WSSV), Vibrio, EMS, and Mortality Syndrome (EHP), without altering water properties or creating harmful residues. This leads to healthier post-larval and juvenile shrimp, which are more resilient during the grow-out stage, resulting in higher survival rates.

Why is UV disinfection preferred over chemical treatment methods in shrimp farming?

UV disinfection is preferred because it is a physical process that does not introduce chemicals into the water, avoiding the creation of reactive residues that could harm the shrimp or the environment. This method ensures that the natural quality of the water is preserved, which is crucial in the sensitive life stages of shrimp.

Do UV systems help maximize yield and cost efficiency?

As a long-term supplier to the shrimp & prawn industry, we have seen countless examples of farmers all over the globe experiencing better feed conversion ratios, a significant reduction in antibiotic use, as well as improved survival rates across all steps of shrimp rearing. All these factors are directly linked to maximizing yield and cost efficiency.

Can UV systems be used for both intake and discharge water in shrimp farming?

The versatility of ULTRAAQUA UV systems makes them capable of disinfecting both intake, process, and discharge water. They are also effective in chlorine and ozone destruction applications, which is important for preventing potential negative impacts on the cultured shrimp.

How do I choose the correct material for the UV reactor?

Depending on the source of intake water, the environment can be very corrosive due to salinity or air humidity. This can be a challenging setting for commonly used materials in UV reactors and control cabinets.

Based on 25 years of experience in seawater disinfection in warm and cold-water environments, ULTRAAQUA has developed the UV stabilized polypropylene (PP), which is resistant to warm seawater due to its non-corrosive construction. For cold seawater and freshwater applications, fully electropolished SS316L reactors are available. This ensures an increased corrosion resistance on the outside surface, and increased UV light performance due to internal reflection on the inside surface.