UV DISINFECTION FOR INTAKE WATER

With water resources becoming increasingly scarcer and more polluted, delivering large quantities of high-quality seafood presents a challenge to many RAS facilities around the world.

Intake water has a crucial role in accommodating high biosecurity standards. It is absolutely essential for thriving aquaculture, as it can potentially contaminate the entire production if treated inadequately – from the hatchery to the rearing tanks.

The small eggs and fry are particularly vulnerable since they are defenseless in the early stages of their life. For RAS owners, even the slightest spread of disease can result in huge financial losses due to lost production, cleaning, and overall downtime until the next batch.

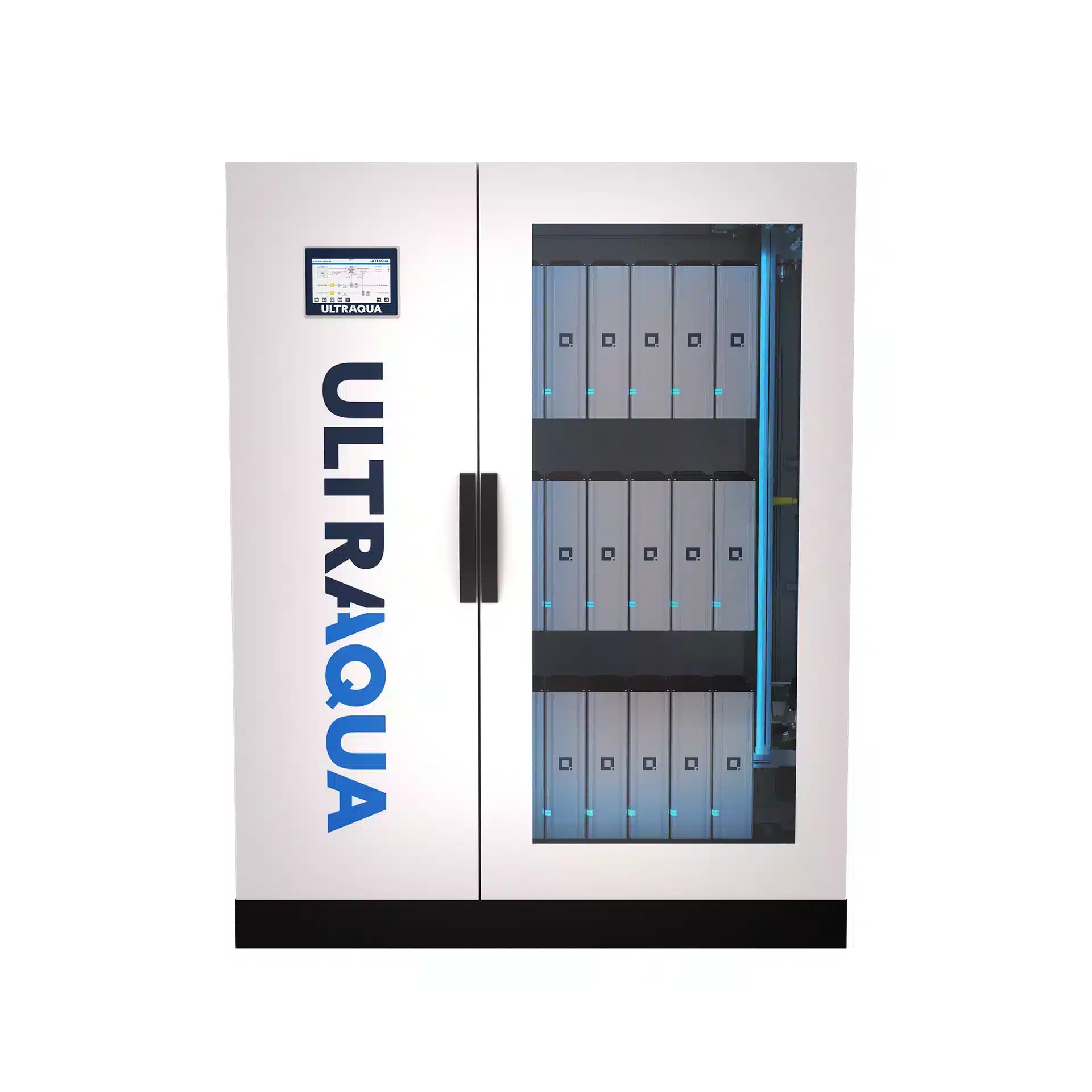

Utilizing UV technology is the most used disinfection method for intake water disinfection due to being a physical process rather than chemical. This means that no unfavored compounds are introduced to the water, avoiding any altering of the water quality which could potentially harm the species. Additionally, it has been proven to be the most environmentally friendly and cost-effective compared to the alternative disinfection methods. ULTRAAQUA UV offers the most advanced aquaculture intake water UV systems designed to reduce any risk of disease, and accommodate even the largest flow rates while providing the user with advanced monitoring capabilities needed in highly controlled environments.

Properly disinfected intake water is just as topical in the increasingly expanding shrimp farming industry, where superior anti-corrosive systems made from UV-stabilized polypropylene have been developed to withstand warm saline water.

UV DISINFECTION SYSTEMS FOR INTAKE WATER

FREQUENTLY ASKED QUESTIONS (FAQ)

Find frequently asked questions regarding UV disinfection for this application by clicking on a question below.

Why is intake water disinfection crucial for aquaculture operations?

Intake water disinfection is crucial because it serves as the first line of defense in maintaining high biosecurity standards within aquaculture operations. Untreated intake water can introduce pathogens that may contaminate the entire production line, from hatchery to rearing tanks. This is especially critical for the protection of small eggs and fry, which are particularly vulnerable in their early life stages.

How does UV disinfection of intake water compare to chemical disinfection methods?

UV disinfection is a physical process that does not introduce any chemicals into the water, maintaining the natural water quality and avoiding potential harm to aquatic species. It is environmentally friendly and cost-effective compared to chemical methods, which can leave residual compounds that may affect both the health of the species and the environment.

What are the cost implications of integrating UV systems into an existing facility?

Integrating UV disinfection systems into an existing aquaculture facility is an investment in the longevity and productivity of the entire aquaculture operation. While there is an upfront cost for the equipment and installation, the long-term benefits include reduced mortality rates, improved water quality, and decreased reliance on chemical treatments. These factors contribute to an increased long-term cost-efficient operation by lowering ongoing expenses related to fish health and water management, enhancing the overall efficiency of the aquaculture system.

How do I choose the correct material for the UV reactor?

Depending on the source of intake water, the environment can be very corrosive due to salinity or air humidity. This can be a challenging setting for commonly used materials in UV reactors and control cabinets.

Based on 25 years of experience in seawater disinfection in warm and cold-water environments, ULTRAAQUA has developed the UV stabilized polypropylene (PP), which is resistant to warm seawater due to its non-corrosive construction. For cold seawater and freshwater applications, fully electropolished SS316L reactors are available. This ensures an increased corrosion resistance on the outside surface, and increased UV light performance due to internal reflection on the inside surface.