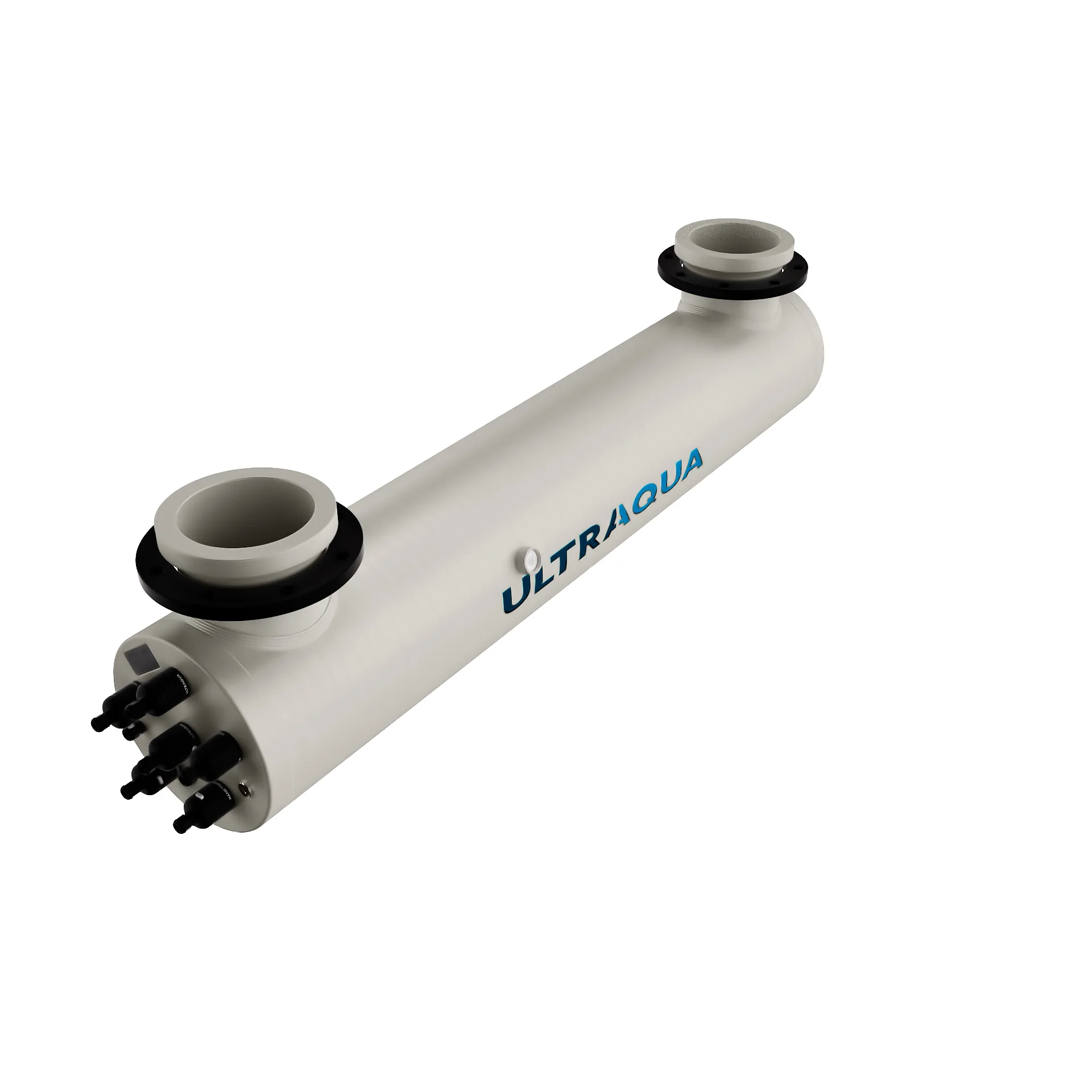

NON-CORROSIVE POLYPROPYLENE REACTOR

MARKET LEADING ENERGY EFFICIENCY

CFD-OPTIMIZED LAMP POSITIONING

HORIZONTAL OR VERTICAL MOUNTING

AUTOMATED ULTRAWIPER™ QUARTZ CLEANING

PRODUCT DESCRIPTION

NON-CORROSIVE PP UV SYSTEMS

The Non-Corrosive PP series is developed specifically for disinfection in harsh corrosive environments. The series is based on over 25 years of experience with corrosive fluids, using Polypropylene material which has proven to be superior in warm salt water and other corrosive environments. The material ensures operational excellence across several applications, due to its exceptional durability and resistance towards temperature and pressure.

Equipped with the automated ULTRAWIPER™ wiping system, the PP series becomes an unbeatable water disinfection solution without the hindrance of complex and frequent maintenance. Paired with a control cabinet from non-corrosive GFRP materials, it is able to withstand even the most corrosive water environments found around the globe.

KEY HIGHLIGHTS

- Non-corrosive Polypropylene material for exceptional durability in highly corrosive environments

- Guaranteed 16 000-hour ULTRATHERM lamp lifetime – Save up to 22% in operational costs

- Automated ULTRAWIPER™ quartz sleeve wiping technology – Stable disinfection process

- Dose pacing technology to automatically modify the power output of the lamps from 100% to 50%

- Advanced design scalability, capable of treating flow rates of up to 6000 m3/h

- Easy maintenance – Quartz sleeve and UV lamp replacements without the need for any tools

- UV intensity monitoring through a non-corrosive PTFE sensor