UV Disinfection for Drinking Water

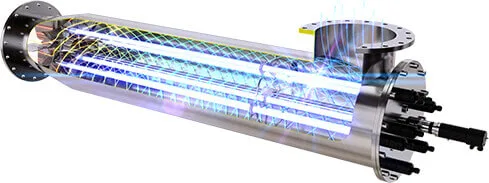

Ensuring proper drinking water is a vital step to protect the public health from dangerous microorganisms. The demand for cost-efficient solutions to provide clean drinking water are at an all-time high and will only increase in the future. UV disinfection solves this safety challenge, being able to meet the strictest requirements regarding bacteria and virus protection.

Heavily chlorinated drinking water has proven to lead to several health complications such as respiratory diseases. While chlorine has proven to be ineffective against Cryptosporidium and Giardia, UV is able to inactivate these pathogens easily with very low doses. This means that UV treatment is capable of inactivating all bacteria, viruses, molds, and spores that may be present in the drinking water.

Operational efficiency is one of the core drivers within the drinking water market. Many facilities and organizations now invest on new assets that yields return on investment based on their operational savings. This has led to manufacturing having to detail their whole life costs over 20 years. Choosing UV as the disinfection method ensures optimal CAPEX and OPEX compared to its alternatives, making UV the best solution for a wide range of installations.

With the support of a well-designed disinfection policy and network, UV can be used as a primary disinfection barrier. In this case, the bias of the disinfection is placed on the UV system with a small residual of chemical disinfection being dosed into the water at the treatment outlet when the flow enters the distribution network, potentially removing the need for contact tanks entirely. This approach can significantly reduce the plant’s overall operational costs as well as result in improved performance.

The second option is to use UV as a part of the multibarrier disinfection policy that uses UV to target specific pathogens, being impossible or too expensive for other technologies to achieve. This could be the use of UV as an exclusive barrier for cryptosporidium, which other technologies such as chlorination have been proven to be inefficient against.

FREQUENTLY ASKED QUESTIONS (FAQ)

Find frequently asked questions regarding UV disinfection for this application by clicking on a question below.

Why should I implement UV technology if I already use chlorine for disinfection?

A common part of the drinking water treatment path is chlorine, which has unfortunately proven to lead to several health complications such as respiratory diseases. Additionally, while chlorine has proven to be ineffective against Cryptosporidium and Giardia, UV treatment can inactivate these pathogens easily with very low doses. UV treatment is capable of inactivating all bacteria, viruses, molds, and spores that may be present in the drinking water while adding no chemicals or by-products to the process.

Why is UV disinfection a preferred method for treating drinking water?

UV disinfection is preferred for treating drinking water because it effectively inactivates all types of pathogens, including bacteria, viruses, molds, and spores, without the use of chemicals. This means there are no harmful by-products like those associated with chlorination, such as trihalomethanes (THMs) and haloacetic acids (HAAs). UV treatment also effectively targets resistant organisms like Cryptosporidium and Giardia, which are not adequately addressed by chlorine. Additionally, UV disinfection does not alter the taste or odor of the water and does not create harmful by-products like trihalomethanes (THMs) and haloacetic acids (HAAs), which can occur with chlorination.

Does UV disinfection impact the operational efficiency of drinking water treatment?

UV disinfection enhances operational efficiency by providing a disinfection method that is cost-effective in both capital and operational expenditures (CAPEX and OPEX). It requires less space than traditional methods and reduces the need for handling and storing hazardous chemicals. This efficiency translates into long-term savings and a lower total cost of ownership over the system’s lifecycle.

Can UV disinfection be used as the primary treatment method for drinking water?

When UV systems are used in conjunction with a small residual of chemical disinfection, UV can potentially eliminate the need for contact tanks, significantly reducing operational costs and improving performance. This makes UV systems capable of being a primary treatment method, with a dual approach to ensure that the water is safe to drink.

Is UV disinfection a sustainable option for drinking water treatment?

UV disinfection is a sustainable option for drinking water treatment because it is a physical process that does not rely on chemical additives. It provides a safe, non-toxic method for ensuring water quality, which is crucial for protecting public health and the environment. Additionally, UV systems are energy-efficient and have a smaller environmental footprint compared to traditional chemical disinfection methods.

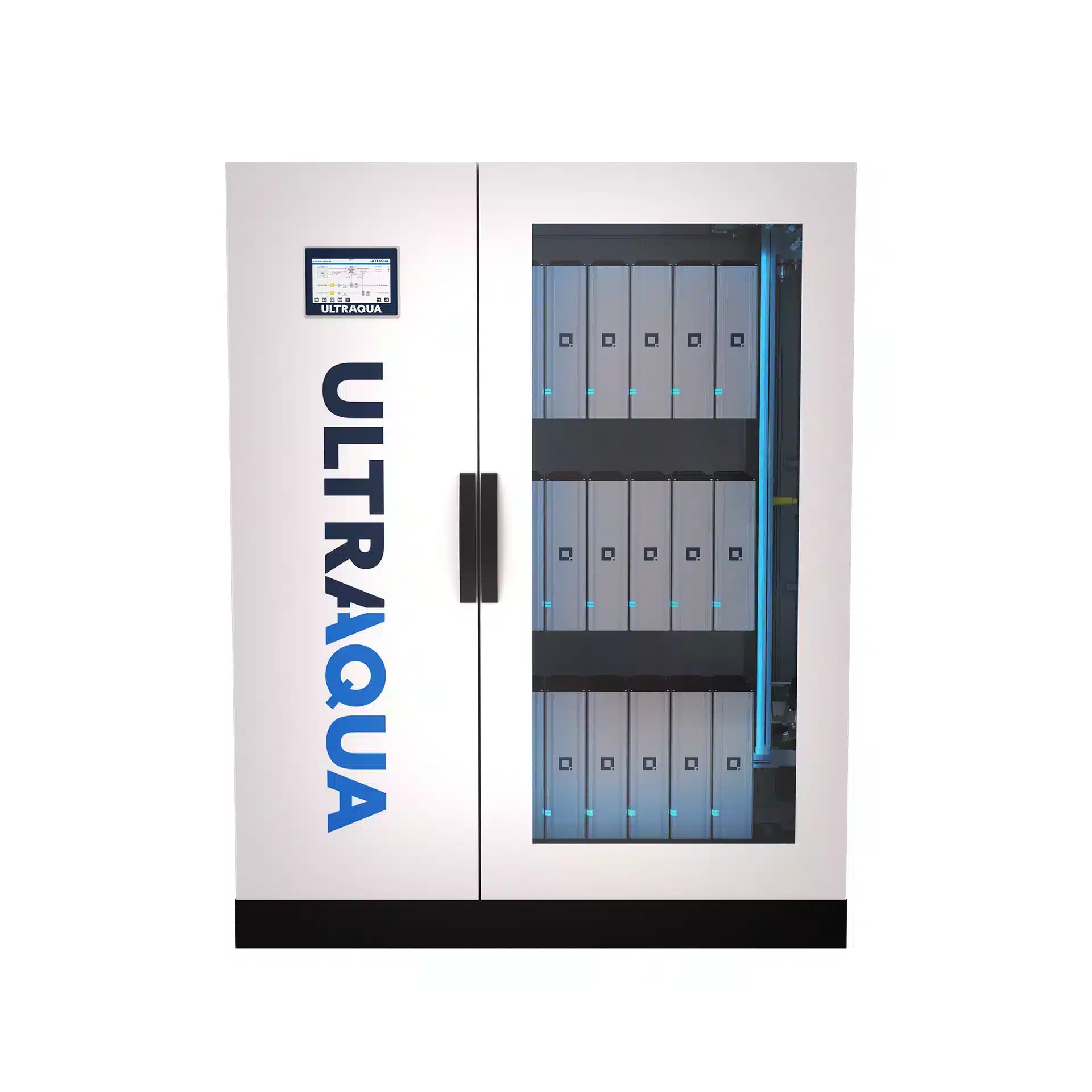

Can UV disinfection systems handle high volumes of water in drinking water facilities?

As modern UV disinfection systems are designed to handle high volumes of water, they are suitable for virtually any scale. The systems can be scaled and customized to accommodate the specific flow rates and water quality requirements of different facilities, ensuring efficient and effective disinfection for large populations.

Is UV disinfection a cost-effective solution for drinking water facilities?

UV disinfection is a cost-effective solution for drinking water facilities, especially when taking long-term operational costs into consideration. While the initial investment might be comparable to or slightly higher than traditional methods, UV systems have lower ongoing operational and maintenance costs. They require less energy, have fewer mechanical parts, and eliminate the need for chemical purchasing and handling, contributing to overall cost savings.