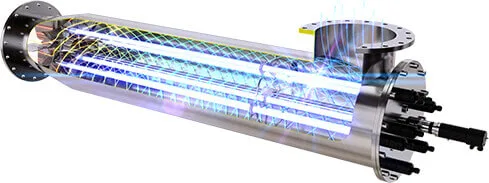

SWIRLFLOW TECHNOLOGY ENABLING HYDRAULIC OPTIMIZATION

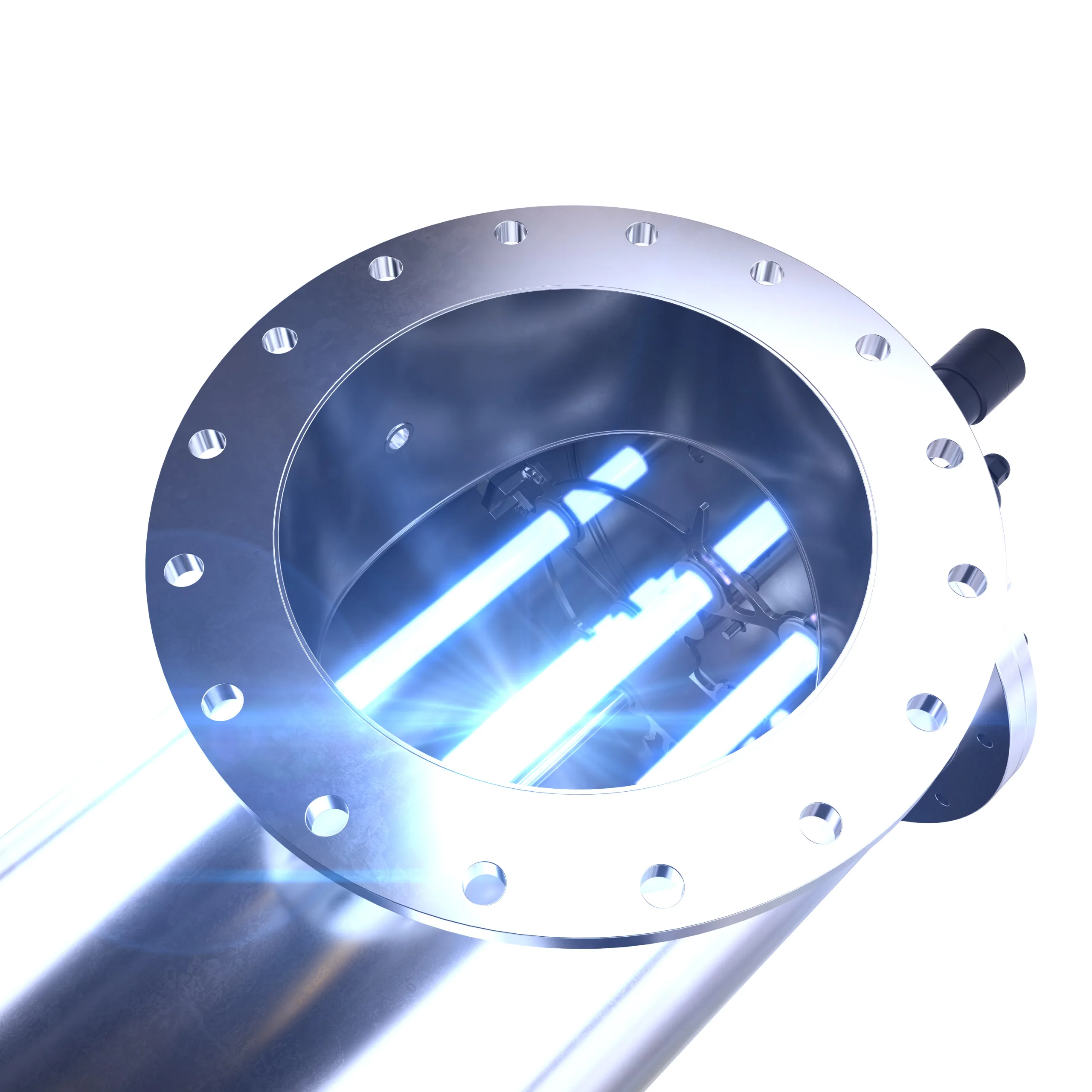

ELECTROPOLISHED STAINLESS-STEEL AISI 316L REACTOR

GUARANTEED 16.000-HOUR LAMP LIFETIME

MARKET LEADING ENERGY EFFICIENCY

CFD-OPTIMIZED LAMP POSITIONING

AUTOMATED ULTRAWIPER™ QUARTZ CLEANING

INTERLOCKING LAMP CONNECTORS

AUTOMATIC DOSE PACING TECHNOLOGY

PRODUCT DESCRIPTION

SSV™ DRINKING WATER UV SYSTEMS

The validated SSV Drinking Water series features the world’s most advanced and efficient UV disinfection technology. Comprehensive biodosimetry testing according to the ÖNORM M 5873-1 standard makes the series offer market leading energy efficiency for municipal drinking water applications. The product range offers disinfection performances capable of more than 4 log with flow capacities ranging from 1 m3/hr to over 4000 m3/hr.

A key feature of the SSV series is the unique patented SWIRLFLOW™ technology which enables optimal UV exposure of all pathogens, ensuring 90% hydraulic efficiency at all water qualities. The SWIRLFLOW™ technology has made the SSV series suitable for a wide UVT range – from 70% to 98%. The internal reflection through the electropolished stainless-steel AISI316L reactor enables up to 30% additional energy savings, combined with automatic dose pacing which can modify the power output of the lamps down from 100% to 50%.

The market leading ULTRATOUCH™ PLC offers the very latest in control and touch-screen HMI technology. With full data logging available, the ULTRATOUCH™ PLC provides complete control of the UV system to the operator, on site or remotely. Additionally, the SSV series PLC controls are easily integrated into SCADA layouts and can be modified by our in-house software engineers to match the most complex requirements.

KEY HIGHLIGHTS

- ÖNORM M 5873-1 – 3rd party bioassay validation

- Unique patented SWIRLFLOW™ technology enabling 90% hydraulic efficiency

- CFD optimized for hydraulic efficiency with minimum head loss

- Operational efficiency with advanced automated lamp dimming

- Automated ULTRAWIPER™ quartz sleeve and sensor window wiping system – Stable disinfection process

- High-grade electropolished stainless steel AISI 316L construction – Up to 30% energy savings with internal reflection

- Guaranteed 16 000-hour ULTRATHERM™ lamp lifetime

- Easy SCADA integration – Connection via ethernet MODBUS

- Easy maintenance – Quartz sleeve and UV lamp replacements without the need for any tools