ABOUT THE CLIENT

DRINKING WATER FACILITY IN SCOTLAND

Hopes Reservoir is located in the scenic Lammermuir Hills, East Lothian, Scotland, and is operated by Scottish Water for the supply of drinking water to approximately 2,500 residents.

The typical daily demand from the site is 2.5 million liters, with additional capacity to supply 4 million liters at times of peak demand.

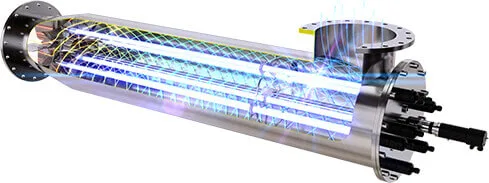

As part of an ongoing water quality redevelopment strategy to ensure continuous improvements, Scottish Water chose to include ultraviolet water treatment as a worthwhile addition to the existing infrastructure, to further increase the quality of the water supply for the local area.

TECHNICAL SPECIFICATIONS

THE CURRENT WATER TREATMENT PATH

The existing system flows raw water under gravity to the works from Hopes Reservoir. Before entering the works building the raw water is dosed with aluminum sulfate, a coagulant to form flocs and remove colloidal particles and micro-organisms from the water. After coagulation, the water flow is divided between twelve pressure filters. This type of filter is fully enclosed and flows downwards through sand media. These pressure filters remove the flocs caused by coagulation from the water, together with any other suspended matter, impurities, and bacteria. Water flows into the top of each filter before passing through the sand media.

As the water passes through the sand, impurities are trapped within the voids between the grains. This causes the media to become progressively choked, as measured by the increasing pressure drop across the filter (i.e. loss of head). Clear filtered water emerges from the bottom of the filter. The sand media requires periodic backwashing to restore the filter to its original condition.

Clean filtered water leaves the building via a 12-inch pipe, which passes through the same chamber as the raw water inlet pipe. A manual isolation valve is located within the chamber. Further downstream, the filtered water is disinfected using sodium hypochlorite.