ELECTROPOLISHED STAINLESS-STEEL AISI 316L MATERIAL

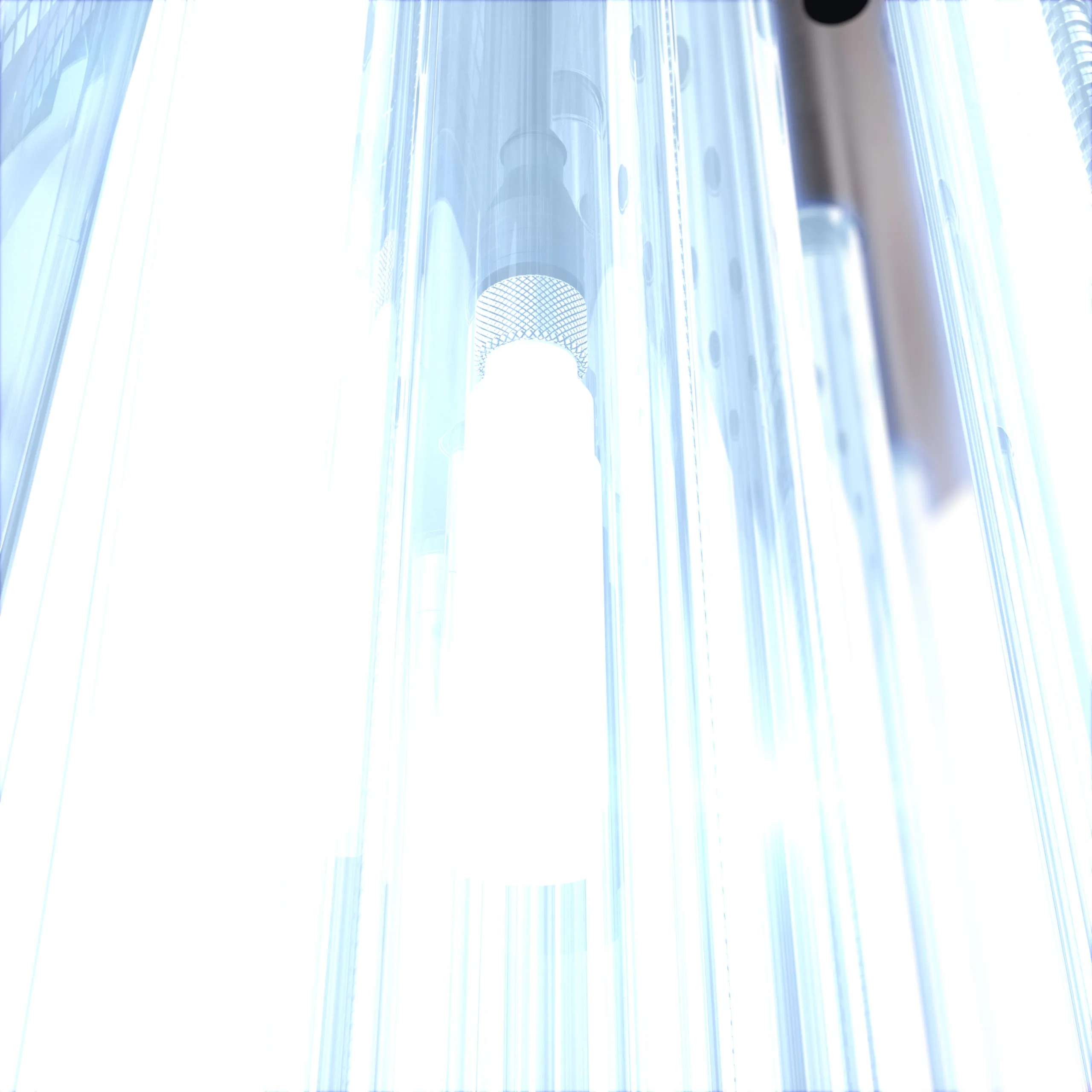

CFD-OPTIMIZED LAMP POSITIONING

AUTOMATED ULTRAWIPER™ QUARTZ CLEANING

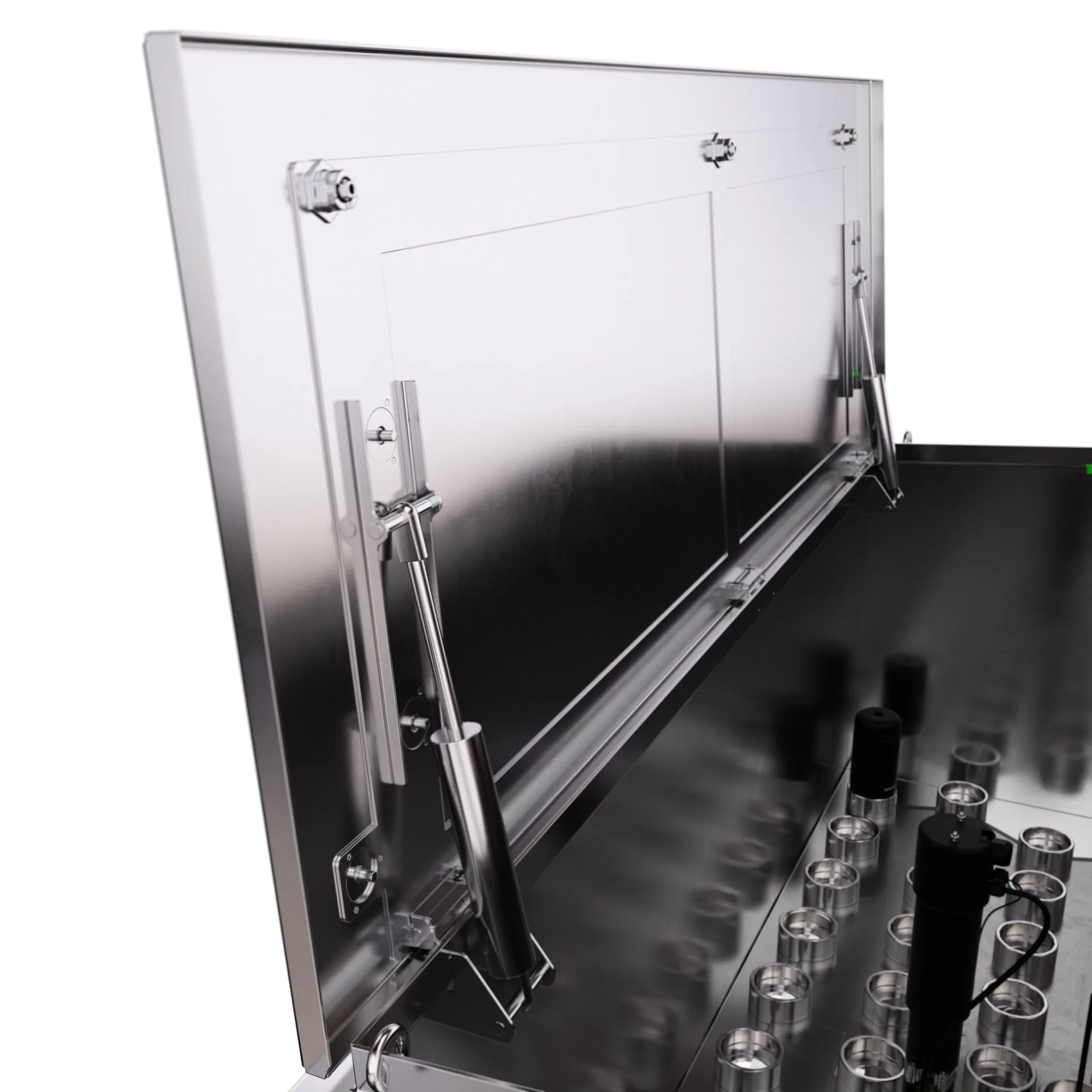

EASY TOP-COMPARTMENT ACCESS

INTERLOCKING LAMP CONNECTORS

SAFE AND STABLE LOCK MECHANISM

MARKET LEADING ENERGY EFFICIENCY

GUARANTEED 16 000 HOUR LAMP LIFETIME

EASY MAINTENANCE AND INSTALLATION

PRODUCT DESCRIPTION

VERTICAL OPEN CHANNEL UV DISINFECTION SYSTEMS

The Vertical Open Channel SS series offers safe, chemical-free disinfection for municipal and industrial wastewater disinfection. The ULTRATHERM™ 16 000-hour UV lamps technology with its cross-row layout ensures complete pathogen exposure with market leading energy efficiency.

The robust, modular shell design provides a range of scaling and retrofitting options for existing water treatment infrastructures, such as old chlorination tanks. For even further construction versatility, an inclined configuration is available, as well as a horizontal version. This makes the design easily scalable and capable of treating flows of virtually any size.

The series features a sealed top compartment where the lamps, quartz sleeves, wiping motor, and UV sensors are easily accessed. This allows for quick, easy, and hygienic maintenance procedures while the system is submerged. Additionally, the automated ULTRAWIPER™ technology ensures clean quartz sleeves with tailored brush heads, ensuring operational efficiency.

KEY HIGHLIGHTS