ELECTROPOLISHED STAINLESS-STEEL AISI 316L REACTOR

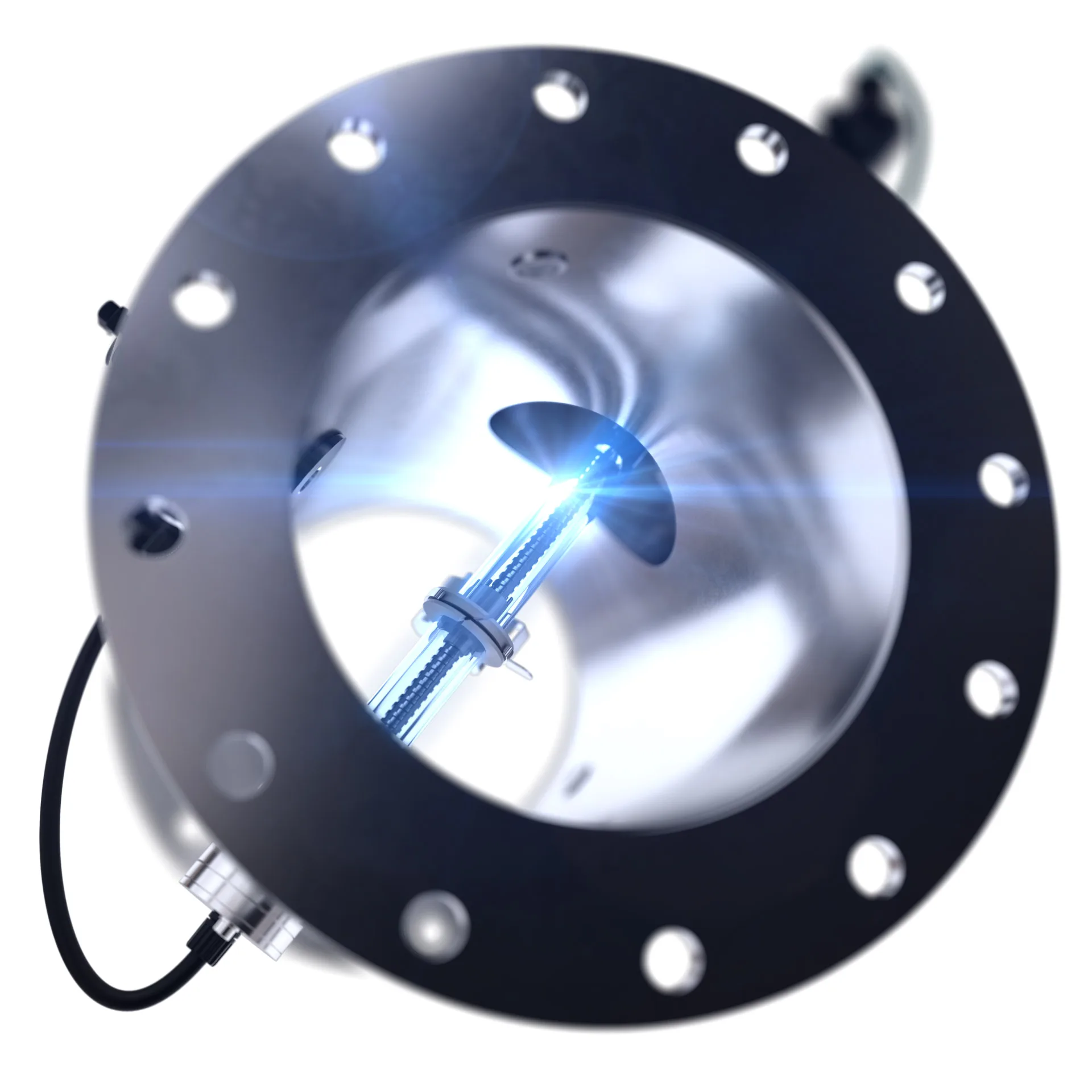

AUTOMATED ULTRAWIPER™ QUARTZ CLEANING

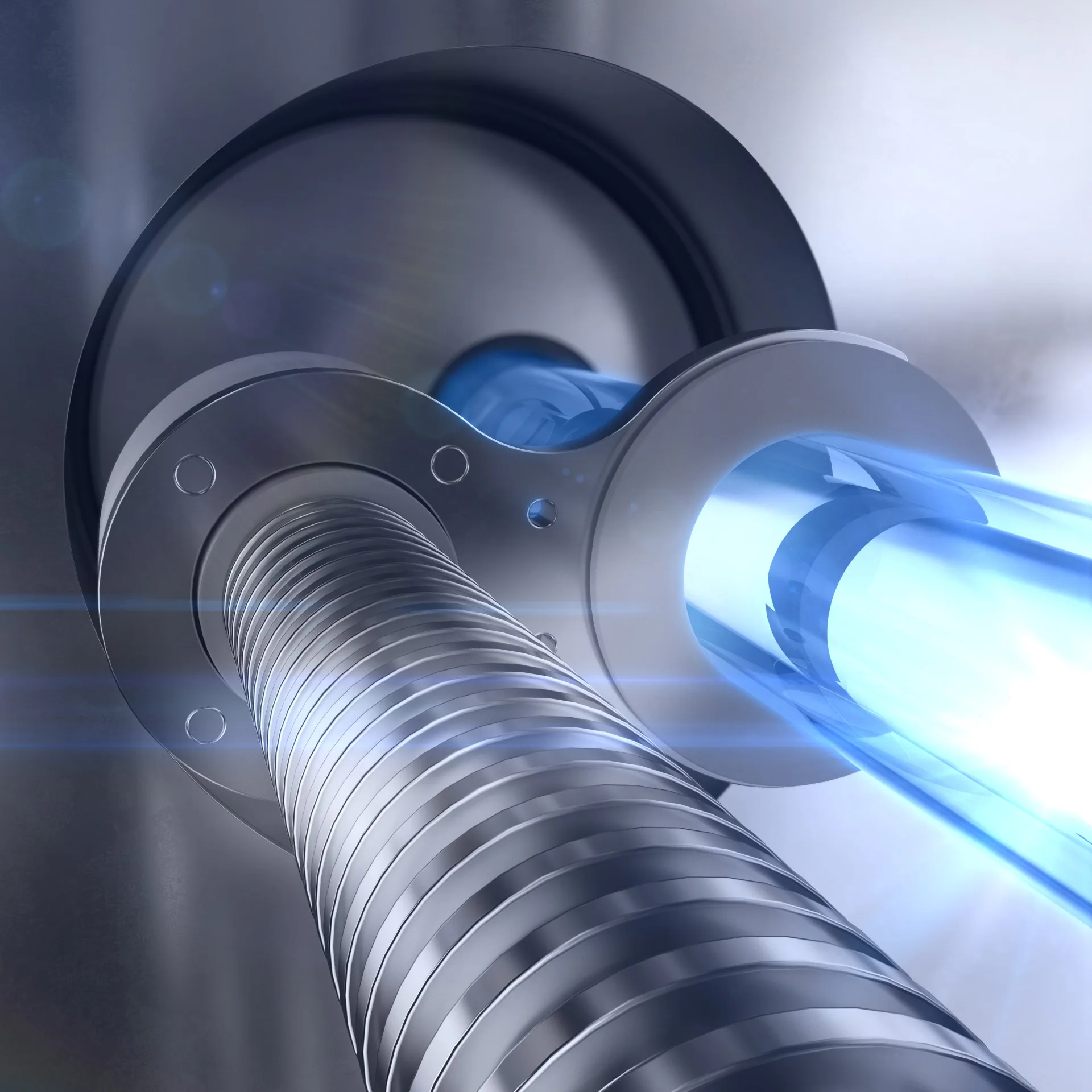

CFD-OPTIMIZED LAMP POSITIONING

HORIZONTAL OR VERTICAL MOUNTING

AUTOMATIC DOSE PACING TECHNOLOGY

EASY MAINTENANCE AND INSTALLATION

PRODUCT DESCRIPTION

MULTIRAY DE-CHLORAMINATION UV SYSTEMS

The MULTIRAY series is based on numerous years of scientific research and R&D activities, optimized for disinfection, chloramine reduction, and crypto/giardia safety in swimming pools. The result is a much lower combined chlorine level, better air quality, and simply healthier water.

Scientific research conducted over the last 10 years has shown that under normal operation in swimming pools, most of the measured combined chlorine levels are composed of organic chloramine compounds. The MULTIRAY ensures a low level of organic combined chlorine from swimming pool water through continuous photolysis, utilizing the pool-optimized medium-pressure lamp technology.

The reactor geometries and electronic control systems have been designed to minimize operating costs. The large, flanged connections and body geometry results in very low head loss even at a high flow rate. The intelligent PLC control enables automatic operational efficiency through lamp dimming based on combined chlorine sensing, time of day/week timers, or UV sensor. This makes the MULTIRAY able of being dimmed and operated based on a setpoint of combined chlorine levels in real time to save energy. During opening hours, it can be chosen to always maintain a minimum UV dose to ensure a barrier for crypto and giardia.

A material selection consisting of high industrial component quality guarantees long-term trouble-free operation in mostly hot, humid, and corrosive pool environments.

KEY HIGHLIGHTS

- UV lamps scientifically optimized for pools – chloramine, cryptosporidium & giardia control

- Energy-saving through electronic ballast capable of lamp dimming based on sensor value, combined chlorine level or timer

- Reactor/flange dimensions fit for pool applications to minimize head loss.

- High-grade electropolished stainless steel AISI 316L construction – Up to 30% energy savings with internal reflection

- Double security against overheating

- Complete control with the customizable ULTRATOUCH control cabinets

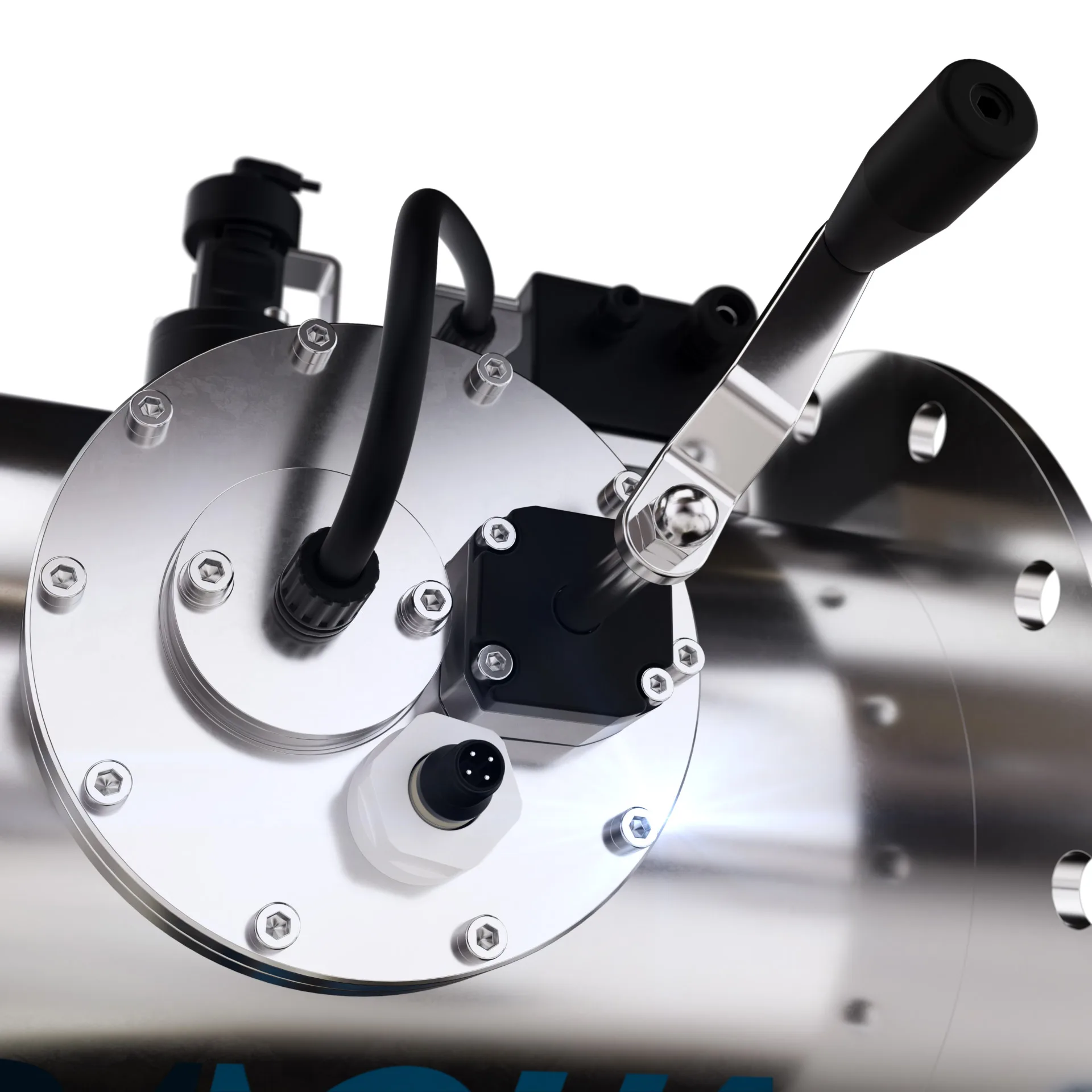

- Leak-proof spindle system for cleaning with proximity sensor control

- Sensor measuring directly in water with valve for service during operation

- Optional – Automated ULTRAWIPER™ quartz sleeve and sensor window wiping system