ABOUT THE CLIENT

SALMON HATCHERY IN SCOTLAND

With two freshwater hatcheries and 42 marine farms around Scotland’s west coast, Orkney and Shetland Islands, Scottish Sea Farms (SSF) is one of the leading producers of premium Scottish farmed salmon. The company has a notable focus on integrating innovative technologies throughout the entire business chain in order to farm as responsibly and as sustainably as possible.

The new 24,000m² hatchery costs roughly USD 80 million and can produce up to 12 million smolts annually. This has made the SSF Barcaldine Hatchery one of the largest and most advanced in the world. Located on the shores of Loch Creran, it is designed to produce bigger, more resilient smolts that are better able to withstand challenging marine environments.

WHAT THE CLIENT NEEDED

A STATE-OF-THE-ART RAS FACILITY

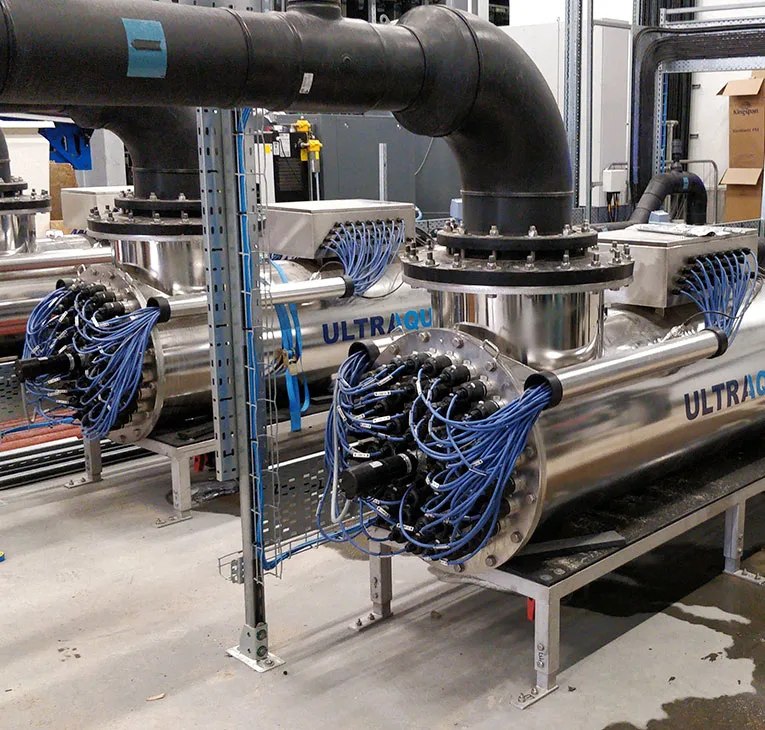

Utilizing UV systems was a perfect fit to support the operations of a well-functioning RAS facility, requiring 24-hour supervision and many years of expertise. Providing more control over the key growth factors of water quality, temperature, flow and light, RAS technology offers farmers the scope to create the optimum environment for their fish.

The new facility will enable SSF to shorten the time salmon spend on-growing at the sea by as much as two months which will further help increase survival rates. It also creates the opportunity for longer fallow periods between generations of fish, contributing to a healthier marine environment for future generations. The facility is sustainably optimized and includes four incubator units and four hatcheries.