What is UV Transmittance (UVT)?

24 October 2022UVT is short for UV Transmittance, which indicates the UV light transmission factor in a water sample. More specifically, UV Transmittance is a measurement of the amount of ultraviolet light at 254 nanometers (nm) that is able to pass through 10 mm of water. The UVT is expressed as a percentage – %UVT. The amount of light that gets through the water sample is an indicator of the general water quality.

Even though it is not always visible to the human eye, all water is capable of having particles that absorb or deflects UV light. The UVT will vary based on the number of compounds in the water which absorbs the UV light, such as humic acids, iron, colloidal solids, and other material.

To simplify, a water sample with a UVT of 90% is significantly clearer than one with a UVT of 10%, as more light is able to pass through the sample.

Why is UV Transmittance important?

UV Transmittance is essential to know as it helps us identify how clean the water is, resulting in better conditions to ensure proper water disinfection. By knowing the UVT of the water to be disinfected, it becomes possible to select the optimal UV system for optimal disinfection conditions.

Microorganism inactivation can be achieved at UV wavelengths ranging from 100 to 400 nm, although a wavelength of 254 nm is proven to be the most effective. Due to this, the UV lamps of almost any UV treatment solution operate at this wavelength, which then becomes the point of reference. This will result in accurate sizing of the UV treatment solution, as UV lamps operate at the same wavelength as used throughout analysing the UVT.

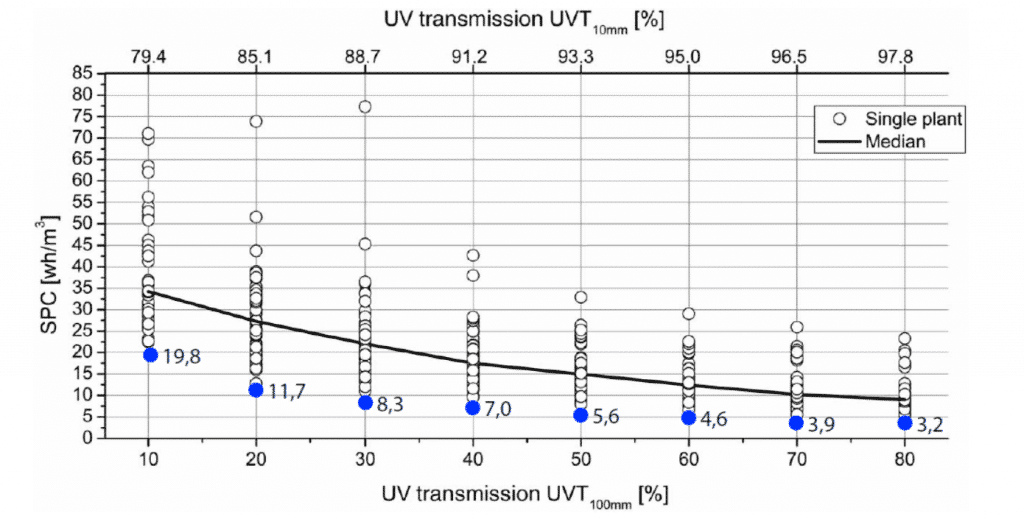

For water disinfection purposes, it is important to note that the UVT should never be 0%. A UVT on such a low level will result in the lamps not being able to penetrate through the water. In order to be effective, the UV rays of the UV disinfection system are required to “reach” all of the potential pathogenic microorganisms, in order to be effective. In general, the lower the UVT, the more UV light is needed, resulting in a higher operating cost due to the required power consumption.

The image above is a particle tracing simulation, showing UV dose exposure of the particles throughout the UV reactor.

Using a UVT analyser for ultraviolet transmission measurement

A UVT monitor is a device that measures the optical clarity of the water at 254 nm. The UVT device can be used to ensure that the UVT is aligned with the applied dose. The UVT is the biggest variable when it comes to the delivered fluence, which is why it is widely used within UV treatment. By doing so, the UV system operator is able to perform better dose pacing as the water may change in quality.

A UVT monitor may be installed for several reasons, with the purpose of helping process operators to better understand their process performance. As UVT is one of the biggest variables regarding cost-efficiency, knowing the UVT continuously is very beneficial, to optimize power consumption.

At ULTRAAQUA, UVT testing is performed by the following approaches:

- Portable UVT testing

Water samples are collected on an ad hoc basic to be tested through the portable UVT transmittance analyser

- Online real-time testing

A device is installed next to the UVT system, which continuously collects samples while the UV is in operation.

How to calculate UV Transmission (UVT) through UVT testing

In the ULTRAAQUA laboratory, we follow this specific UVT testing procedure, to select the most suitable UV system. Getting the sizing right is critical, to make sure that the water is disinfected according to the disinfection protocol, as well as hitting the correct power consumption.

Firstly, a water sample is sent to our laboratory, which is being carefully handled by our specialists.

Secondly, The amount of light able to pass through the water is calculated through a UVT transmittance analyzer, where the UVT is being determined (0-100%). Distilled 100% UVT water is used in comparison as the benchmark.

The UVT measurement can now begin, where the UVT values from the water sample is tested in intervals, by retaining the water sample in a UV system. The values derived over time are now plotted into a graph, showing how the UVT changes in relation to the retention time in the UV system.

The graph generated from this process makes it possible to choose the exact required UV system setup.

As different UV intensity is required for inactivating different bacteria and viruses, analyzing the UVT is essential. The UV intensity requirements vary a lot based on industry and application. The average values for selected microorganisms can be seen here:

- Coliform bacteria, legionella, fecal bacteria, streptococci, nematodes (eelworms) and yeasts, etc. – 3 – 40 (mJ/cm²)

- Pathogenic fungi, such as fusarium, pithium, phytophtora, etc. – 30 – 120 (mJ/cm²)

- Viruses such as cucumber virus, olpidium, cholera, etc. – 60 – 250 (mJ/cm²)

Sizing the right UV system for the measured UVT

As mentioned, it is essential to know the UV transmittance when sizing a UV system for any given case. By determining the UVT in advance, it becomes possible to identify the right UV system with the appropriate number of lamps, power consumption, additional features etc., which is required to ensure the desired purity of the water. In this way, the optimal operating cost can be achieved, while living up to the defined disinfection requirements.

As different pathogens require different UV doses to be inactivated, it must be clear which pathogens are to be inactivated in any given case. Additionally, it is important to note that the relationship between the dose and log removal is not linear. It takes a much higher dose to achieve log-4 removal compared to log-2 removal.

There are a lot of factors to be assessed in order to select the best suited UV systems, such as location, application, flow rate, UVT and targeted bacteria. ULTRAAQUA is always available to assist in assessing all relevant factors including the UV transmission and UV dose, to ensure that the optimal UV system is selected. By sending a water sample from your site to our headquarters in Denmark, our scientists are able to assess the bacteria to be targeted in our state-of-the-art laboratory, as well as determining the desired log reduction and/or pre-filtration.

ULTRAAQUA offers multiple UV system series for low-UVT environments, providing excellent disinfection under cost-efficient conditions. In environments with very low UVT, normal UV systems are not able to eliminate pathogenic microorganisms due to the low transmission of UV light. UV systems such as the LOW UVT Series has CFD optimized lamp positioning, which offers maximum hydraulic efficiency with minimum head loss, eliminating any chance of ‘dark areas’ with untreated microorganisms.