Using UV Disinfection for Water Treatment in the Aquaculture Industry

17 November 2022Today, the aquaculture industry represents more than 47% of the world’s seafood consumption, and the number continues to grow.

According to a report from The United Nations Food & Agriculture Organization (FAO), aquaculture is the fastest-growing food production sector in the world. The report states that by 2030, the world will eat more than 20 percent more fish, compared to 2016. By 2030, aquaculture production is projected to reach 109 million tons – a significant growth rate of 37%.

Unfortunately, the swift rise of aquaculture has called the practices of the industry into question. This is due to the environmental strain caused by outdated practices, which is demonstrated by the questionable product quality and sustainability conditions. There is a solution for this, however.

Food production in aquaculture does not have to rely on outdated practices. By utilizing sustainable technologies such as UV disinfection, both the production and climate can be protected.

Utilizing UV disinfection in the aquaculture industry

With water resources becoming increasingly scarce and polluted, Recirculating Aquaculture (RAS) facilities and Shrimp & Prawn facilities worldwide are facing an increasing challenge of delivering large quantities of high-quality food. However, by implementing sustainable technologies such as UV systems, chemical-free disinfection can assist greatly in overcoming these obstacles.

By utilizing UV technology, RAS and Shrimp & Prawn facilities all over the globe have become able to meet the strict requirements for microorganism control in a chemical-free and sustainable manner. With UV disinfection, no unfavored compounds are introduced to the water, which means that the selected species can thrive in properly disinfected water with no potentially harmful substances present. Choosing UV offers the guarantee of a cost-effective and sustainable choice, able of accommodating extremely large flow rates while providing full monitoring control and overview of the facility.

Initially, ensuring microbiological safety of the intake water is critical to ensure that no diseases can enter the controlled environment. Even the slightest outbreak of harmful microorganisms can evolve to cause significant economic losses. It is essential for aquaculture facilities to ensure proper water intake conditions as an initial step, to avoid potential contamination of the entire production. Especially in the early stages of the life of the species, where eggs and fry are particularly vulnerable and defenseless. In the worst case, a complete production loss due to contamination can become a reality, leading to substantial financial losses.

Common water treatment problems in complex aquaculture environments

Achieving successful conditions for RAS/Shrimp & Prawn facilities is not a simple task. The increased demand within both types of facilities has caused increased production volumes, usually leading to increased stocking densities and growth in fatal diseases.

Creating optimal conditions for reared species requires advanced disease control due to continuous water reuse, taking the accumulation of species dropping as well as the used nutrients into account. If not properly handled, these facilities can become breeding grounds for various bacteria and viruses, potentially contaminating the entire production resulting in significant financial losses.

Adding more nutrients to the diet usually induces further contamination, which leads to the conclusion that the most successful disease control is to ensure solid water disinfection protocols to create excellent water quality throughout the entire production process. Notably, for the hatcheries and nurseries, proper rearing of post-larval and juvenile shrimp leads to a more resilient grow-out stage, resulting in higher shrimp survival rates further down the line.

Choosing the right UV systems makes it possible to ensure efficient water disinfection for the different stages of shrimp farming – hatcheries, nurseries, or intensive grow-out facilities, being ideal for both intake, process, and discharge water. This has led farmers all over the globe to experience better feed conversion ratios, a significant reduction in antibiotic use, as well as improved survival rates across all steps of shrimp rearing. Addressing all these factors is critical for ultimately maximizing yield and cost efficiency.

This creates peace of mind for shrimp farmers worldwide, knowing that all common shrimp diseases such as White Spot Syndrome (WSSV), Vibrio, EMS, Mortality Syndrome (EHP), and more are under full control.

Controlling aquaculture diseases by applying the correct UV dose

The first step towards aquaculture biosecurity is by applying the right UV dose to inactivate the targeted bacteria and viruses.

UV disinfection inactivates microorganisms by damaging their DNA and RNA, which prevents them from causing any harm. The inactivation of microorganisms by UV is dependent on the applied UV dose, defined in mJ/cm2 or J/m2, consisting of the UV light intensity, residence time, and UV transmittance.

It is important to mention that there are mechanisms in the cells that repair these damages to the DNA/RNA. Because of this, the lower the UV dose applied to the microorganism, the higher the risk is for photoreactivation and dark space repair mechanisms. However, research has shown that there is almost no risk of photoreactivation when a UV dose of at least 15 mJ/cm2 is applied, by any common UV lamp technology.

To effectively disinfect the water and inactivate the targeted microorganisms, it is crucial to get the UV dose right. In the salmonid industry, the most commonly targeted microorganisms with a minimum 3 log (99,9%) reduction are:

- Infectious Pancreatic Necrosis Virus (IPNV)

- Aeromonas salmonicida

- Vibrio anguillarum

- Infectious salmon anaemia virus (ISAV)

- Vibrio salmonicida

- Yersinia ruckeri

As one of the most UV-resistant viruses, the IPNV requires a UV dose of at least 246 mJ/cm2.

UV doses for other common aquaculture diseases include the following:

Bacterial

- Aeromonas salmonicida – 5.0 mJ/cm2

- Aeromonas hydrophila – 5.0 mJ/cm2

- Flavobacterium psychrophilum – 126 mJ/cm2

- Vibrio salmonicida – 1.5 mJ/cm2

- Vibrio anguillarum – 4.0 mJ/cm2

- Pseudomonas Fluorescens – 11.0 mJ/cm2

- Renibacterium salmonicida – 20.0 mJ/cm2

- Bacterial Kidney Disease (BKD) – 60.0 mJ/cm2

Viral

- Infectious Salmon Anemia Virus (ISAV) – 10.0 mJ/cm2

- Infectious Pancreas Necrosis Virus (IPNV) – 250 mJ/cm2

- Nodavirus – 200 mJ/cm2

- Infectious hematopoietic necrosis Virus (IHNV) – 30.0 mJ/cm2

- Atlantic Salmon Paramyzo Virus – 240.0 mJ/cm2

- Heart Sceletal Muscle Inflammation (HSMI) – 250.0 mJ/cm2

- Nervous Necrosis Virus (NNV) – 70.0 mJ/cm2

Utilizing aquaculture water treatment systems for R&D activities in Shrimp & Prawn farming

Located in Vietnam, Viet-Uc operates one of the largest shrimp hatchery operations in the world, specializing in the hatchery, nurturing, and incubation of shrimp. By continuously investing in new technologies, Viet-Uc has become able to transform Vietnam’s shrimp industry through scientific innovation. The efforts have resulted in excellent water treatment conditions, ensuring that the shrimp can thrive under full control.

The overall aim was to increase the growth conditions and robustness of the shrimp to ultimately increase production yields. To do this, five commercial-scale experiments were established, providing the best possible conditions for the shrimp to thrive through health management and selecting breeding.

To create the future of shrimp & prawn farming, utilizing state-of-the-art UV technology was a necessity, as the many benefits of UV systems are perfectly aligned with aquaculture disinfection control, being able to manage the overall biosecurity measures.

Utilizing the non-corrosive UV systems proved to have a substantial positive impact on the biosecurity of the facility. Continuous data collection and analyses of the water proved that the UV systems could control the microorganism levels in the water.

The results were improved rearing technologies, which included:

- A shrimp survival rate of over 85%

- A feed conversion ratio reduced to 1:3

Not only has the profitability of the rearing systems increased – it has also resulted in a reduction in water consumption and control of vibrio numbers, which is expected to improve long-term sustainability.

The project is a testimony of how important the role of UV systems is for shrimp & prawn facilities in the future. Read more about the project here.

Using UV sterilizers for aquaculture at the largest eel farm in the world

Located in China, the largest land-based RAS eel system in the world is in full operation, set to reach an annual production of 15.000 tons of eels. To ensure thriving eels in the RAS system, the best possible water treatment conditions were required. To reach these high standards, it was evident that the best possible disinfection equipment on the market needed to be included. The water treatment conditions had to remain of excellent quality and ensure complete biosecurity while taking energy-efficiency into account.

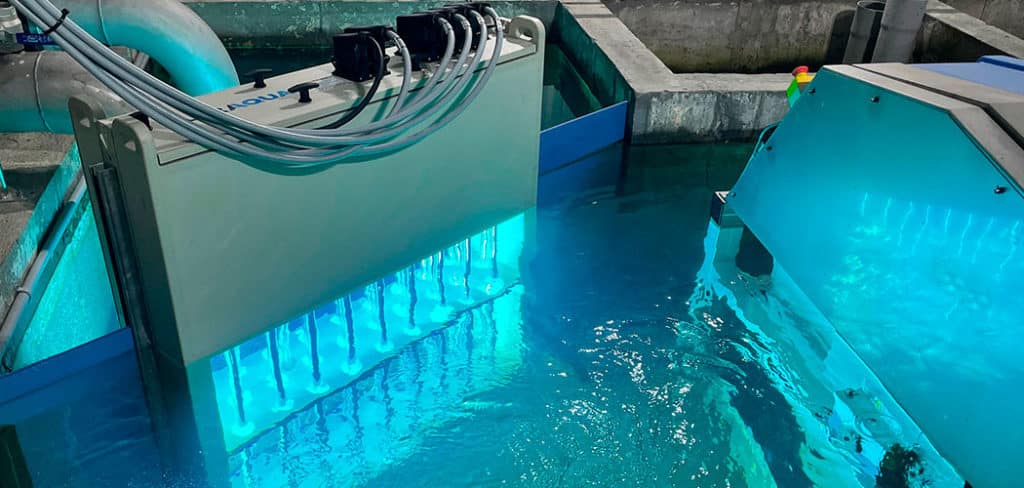

The facility chose to install 158 aquaculture disinfection systems in total, including 3 different types of UV systems in both open channel and closed vessel construction, consisting of either stainless steel/polypropylene material.

All the 158 UV systems are in operation at several sections around the facility, ensuring properly disinfected water for the glass and adult eels. Read more about the project here.

UV systems optimized for aquaculture water treatment

As of today, the UV systems from ULTRAAQUA disinfect over 100.000 m3/h of RAS water per hour globally. No matter the climate, type of water, flow rate, or alike, a UV system for your requirements is available.

The product range diversity makes ULTRAAQUA able to accommodate virtually any requirement in both closed vessel and open channel systems, available in both stainless steel and polypropylene material. The most suitable disinfection solution is just a system selection and sizing away, whether it may be influent, effluent, or process water for installation or retrofitting in your project design.

Particularly for aquaculture applications, choosing a UV system with reactor material consisting of PP (Polypropylene) material ensures operational excellence due to the exceptional durability and resistance against temperature and pressure in corrosive environments.

The following three UV system ranges are optimized especially for aquaculture applications:

- The Closed Vessel PP (Polypropylene) series

- The Open Channel PP (Polypropylene) series

- The validated Closed Vessel (SS/PP) series for intake water disinfection

Read more about the complete range of systems for aquaculture water disinfection by clicking here.

If you wish to hear more about what UV system is optimal for your treatment processes, please use the contact formula below. Our sales engineers are ready to assist with finding the right solution for your disinfection requirements.