How to Choose the Right UV system for Recirculating Aquaculture Systems (RAS) Intake Water

11 November 2021Aquaculture is the fastest growing food production sector in the world according to The United Nations Food and Agriculture Organization (FAO) report. The FAO’s report states that by 2030, the world will eat 20 percent more fish than in 2016. By then, the aquaculture production is projected to reach 109 million tonnes, which is a growth rate of 37 percent compared to 2016.

This will lead to a growing land-based aquaculture, including farming in Recirculating Aquaculture Systems (RAS). RAS will play an even bigger role in the future of aquaculture as it is able to:

- Minimize the threats of cultured fish escaping

- Improve the control of diseases and parasites

- Create better management of water quality (temperature, oxygen rate, nutrient, and suspended solids content)

- Improve the control of nutrient releases in the environment

Fish growing in controlled environments in tanks, often at high densities, sets high requirements for the quality of the water and equipment performance.

In Recirculating Aquaculture Systems (RAS), microbiological safety of the intake water is crucial to guarantee that no diseases are introduced into the controlled environment, as it poses a huge threat to the high valued production which can lead to significant economic losses. A commonly used disinfection method for protecting the intake water supply is ultraviolet (UV) disinfection, due to its vast number of advantages.

Here are five key factors to assist you in choosing the right UV disinfection system for Recirculating Aquaculture Systems (RAS).

1. Ensuring sufficient pre-filtration prior to the UV treatment

UV disinfection is an extremely effective method against pathogenic microorganisms. However, in many cases UV requires sufficient pre-filtration prior to the UV treatment, to filter out larger particles and solids that could create a shadowing effect (shielding) for the potentially harmful microorganisms, preventing them from receiving the necessary UVC light exposure.

The correct pre-filtration method and mesh/pore size are dependent on many factors like the flowrate, the number of suspended solids, the type of intake water and the UV transmittance. UV transmittance (UVT) describes the effectiveness of UV disinfection, by measuring the percentage of light that passes through a water sample (often 10mm) at the wavelength of 254 nm.

UVT can vary significantly between seawater, brackish water, freshwater and the location of the intake. As an example, surface water is coloured by humic substances in many places in Scotland and Norway. A UVT value below 60% is not unusual for the intake water, which means that the UVT in the RAS will be even lower.

Bacteria and viruses also vary in size which must be taken into account when designing pre-filtration. Especially in salmon farming, there has been a growing demand for Ultrafiltration (UF) systems as it is capable of removing bacteria and viruses from the water up to 4log (virus removal). UV treatment and Ultrafiltration combined are capable of creating the so called ‘double-barrier’ against the diseases as they are complementing each other.

Guidelines by the Norwegian Veterinary Institute recommend as a minimum, that < 300 µm filtration/screening should be applied before UV treatment. However, the general rule of thumb is still to have a prefiltration down to 40 microns and 3 NTU in turbidity.

2. Correct sizing of the intake UV system

Correct sizing of the UV system is the most important factor for providing a protective ‘firewall’ against microorganisms in the intake water treatment system. Correct sizing involves several factors, including a correctly applied UV-dose, lamp technology, hydraulic efficiency of the UV system and its approvals to be employed in aquaculture intake.

How to apply the correct UV dose

UV irradiation inactivates microorganisms by damaging their DNA and RNA, which prevents them from reproducing and causing infection. The inactivation ability of microorganisms by UV is dependent on the applied UV dose (also called fluence), usually as mJ/cm2 or J/m2, which is the product of UV light intensity, residence time and UV transmittance through water. The DNA absorbance is high between a germicidal range of 200 – 300 nm which will result in an efficient disinfection primary at 254 nm.

There are mechanisms in cells that repair damage to the DNA/RNA. The lower the UV dose applied for a microorganism, the higher the possibility for photoreactivation (light catalysed repair) and dark space repair mechanisms. However, research has shown that there is almost no potential for photoreactivation above a UV dose of 15 mJ/cm2 by using any common UV lamp technologies.

It is crucial to understand the target UV dose, in order to effectively disinfect the incoming water to the farm. In general, Bacteria is more sensitive to UV light than most other viruses. As an example, in the salmonid industry the most commonly targeted microorganisms with a minimum 3 log (99,9%) reduction are:

- Infectious Pancreatic Necrosis Virus (IPNV)

- Aeromonas salmonicida

- Vibrio anguillarum

- Infectious salmon anaemia virus (ISAV)

- Vibrio salmonicida

- Yersinia ruckeri

The IPNV is also one of the most UV resistant viruses reported in scientific literature, requiring a UV dose of minimum 246 mJ/cm2.

How to choose the best lamp technology for the intake water UV system

UV systems based on amalgam low pressure high output UV lamps (LPHO) provides monochromatic UV irradiation at 253,7 nm, which makes them the most commonly applied systems for disinfection in aquaculture. UV irradiation based on low pressure lamp technology can also be applied for destroying ozone residuals. Ozone residuals are destroyed with UV light between the wavelengths of 250 – 260 nm.

UV systems based on medium pressure lamp technology that supply UV light at a broader spectrum (200 – 400 nm) are also available, but not so commonly used for disinfection in land-based aquaculture due to their higher operating cost in continuous operation.

Compared to the amalgam low pressure high output lamps (LPHO), the medium pressure (MP) lamps consume more electrical energy per unit of germicidal light output than LPHO lamps requiring 2-3 times more power. MP lamps generally only convert up to 15% of their input watts into usable UV-C watts, whilst low pressure lamps can be up to 40% efficient. Additionally, the higher operating temperature of MP lamps (up to 900°C) can increase the fouling of the quartz sleeves. This increases the need for sleeve cleaning, resulting in a higher frequency of replacing fouled components such as lamp sleeves and sensor windows.

UV systems based on MP lamp technology has its advantages when the application requires high UV intensity in a small footprint. The best example is a well-boat installation, as well as other applications where the installation space is very limited, and continuous operation is not required.

The decision to use a UV system based on a specific UV lamp technology should be driven by operational and design advantages, taking the UV lamp characteristics and especially the site-specific conditions into consideration.

Ensuring optimal hydraulic efficiency of the UV system

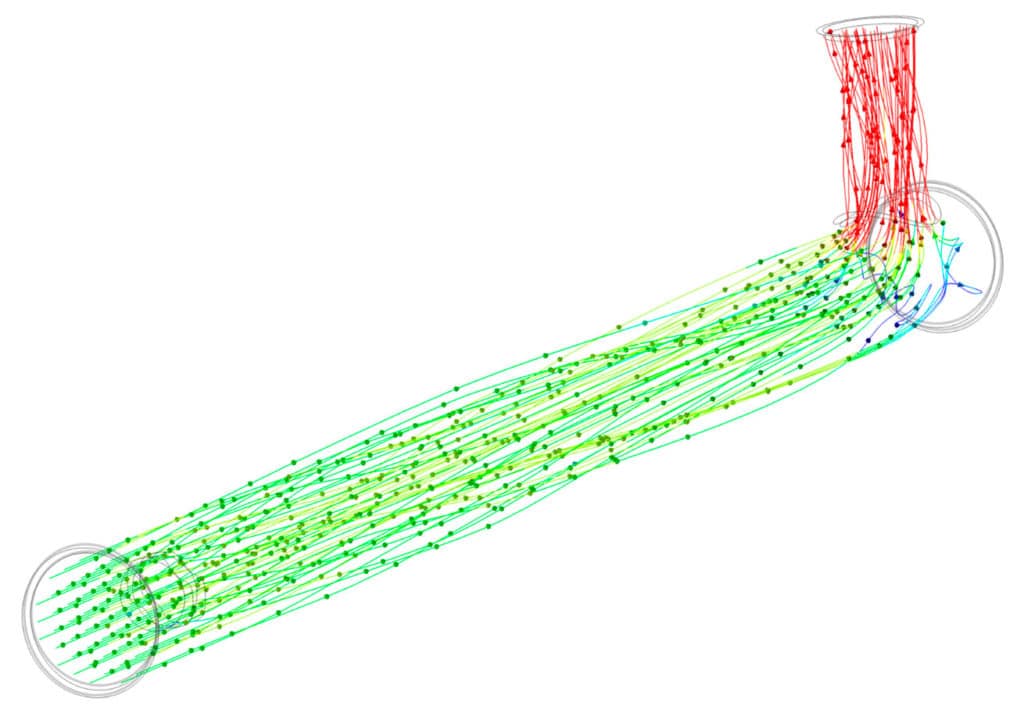

Hydraulic efficiency means optimal and equal UV exposure of all possible pathogens passing through the chamber with a minimal pressure drop.

Problems with achieving uniform mixing of the water is often a result of non-optimised flow velocities throughout the UV reactor caused by a wrong reactor configuration, and a UV lamp configuration that does not match the characteristics of the water. As an example, a UV lamp arranged cross to the inlet flow will result in a very short retention time in both sides of the UV lamp and near the sides of the reactor wall.

UV lamps arranged parallel to the inlet flow provides an extended retention time, resulting in a more uniform distribution of the flow, leading to uniform dose distribution resulting in close to ideal performance.

The uniform mixing to further increase the UV dose is often strengthened by using internal baffles of guides. The final hydraulic behaviour of the water within the UV reactor is analysed by using Computational Fluid Dynamics (CFD analysis), as seen in the image above.

To sum up, the overall UV dose delivered by the different reactor configurations and the performance ratios will fluctuate due to different water UV transmittances and flow rates as well as varying UV lamp intensities.

Acquiring aquaculture specific UV system approval

As there are numerous UV system manufacturers in the world, certificates provided by trusted companies becomes topical, to ensure the validity of the manufacturers products.

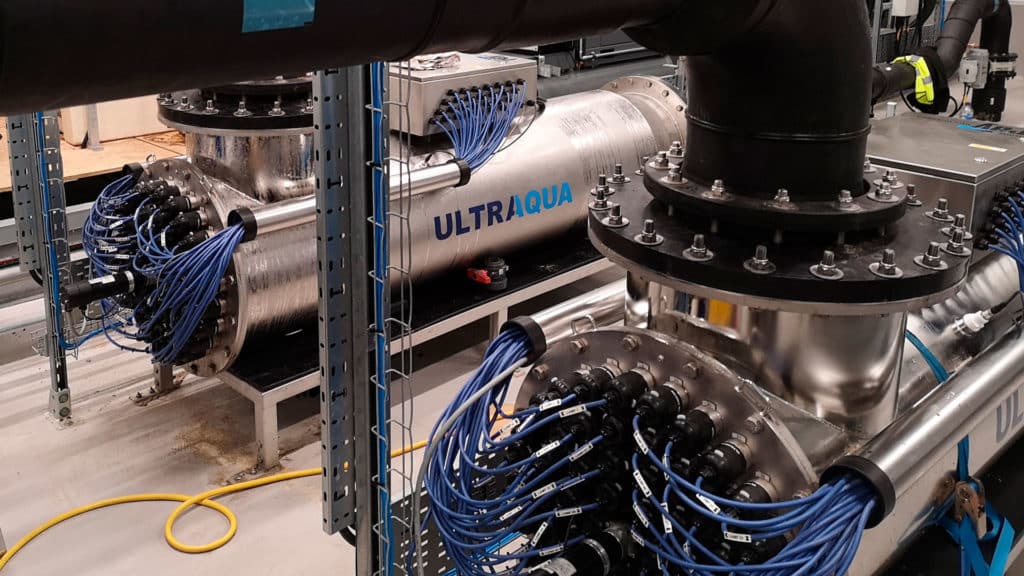

The ULTRABARRIER UV Systems from ULTRAAQUA has officially been approved by the Norwegian Veterinary Institute (NVI). The NVI is a biomedical research institute and national leading centre of expertise in biosecurity of fish and land animals.

Additionally, the technology has been verified for water treatment, through the EU Environmental Technology Verification (ETV) programme. The ETV is a validation that verifies technologies through qualified third parties, using test results to ensure that the environmental technology performance is scientifically verified.

3. Operational optimization of the UV disinfection system

Looking into operational optimization of the UV disinfection system is beneficial for several factors such as cost-efficiency, saving time, and increased security.

An important economic aspect is looking into how to run the UV system in an energy efficient way while maintaining the required UV dose level. The UV system should be running based on the incoming water flow and targeted UV dose. For example, if the flow rate is not at its peak, the UV system should be able to dim the lamps to save energy while maintaining the targeted UV dose, a feature also known as ‘dose pacing’. Additionally, it should be able to give signal for the flow relay to stop the flow in fault cases.

According to the NVI approval, it is mandatory to connect the flow relay to a valve or a similar device that controls the water flow through the UV unit.

How to monitor UV disinfection system performance

The UV system must be equipped with a proper monitoring system in order to monitor the status inside the reactor. UV intensity, flow rate, lamp operating hours, UV dose, individual UV lamp performance and chamber temperature should be continuously monitored by the system’s PLC. Additionally, the following data should be kept in a log as a minimum:

- Date and time

- Temperature

- Irradiance value

- UV dose

- Current flow

- Maximum allowed flow

- UV dose set point

The performance impact of an automatic wiping system in a UV disinfection system

As mentioned earlier, the incoming water characteristics can vary significantly. The UV system will lose its optimal disinfection capability if there are deposits on the quartz sleeves protecting the UV lamps.

There are different types of fouling depending on the source of the water. Generally, an advanced robust automatic wiper system is effective against even the most tenacious scaling without the need for CIP (clean-in-place) chemical cleaning. This leads to elimination of handling hazardous chemicals, additional expenses, downtime, and operation costs while keeping the system running.

How to choose the correct material for a UV reactor and control cabinet

Depending on the source of intake water, the environment can be very corrosive due to saline or air humidity. This can be a challenging setting for commonly used materials in UV reactors and control cabinets.

Based on 25 years of experience within seawater disinfection in warm and cold-water environments, ULTRAAQUA UV has developed the UV stabilized polypropylene (PP), which is resistant material for warm seawater applications due to its non-corrosive construction. For cold seawater and freshwater applications, the ULTRABARRIER UV systems are made of inside and outside electropolished SS316L. This ensures an increased corrosion resistance on the outside, and increased UV light performance due to internal reflection on the inside.

All control cabinets are built from Glass Fiber Reinforced Plastic (GFRP) with passive or active cooling, causing the insides of the cabinets to be protected from any external factors.

4. Maintenance of the UV disinfection system

Effective UV disinfection requires scheduled maintenance of the UV system. The maintenance frequency varies a lot between the different manufacturers, depending on the power supply, robustness, and reliability of the system.

All ULTRAAQUA UV systems are designed to require an absolute minimum of maintenance, using robust and durable components which provides exceptional operational convenience. Decades of research, development and innovation has made it possible to provide our customers with reliable systems that are inexpensive to install and operate, as well as sufficiently maintenance-free to be usable by non-specialists.

5. Proper communication between the manufacturer and end-customer

Last but not least, the importance of proper communication between the UV system manufacturer and the RAS system operator can’t be underestimated.

Picking a supplier with full technical support is extremely critical in case of emergencies, where quick operational support is needed. This emphasizes the need for 24-hour support with technical engineers ready to assist no matter the time zone.

ULTRAAQUA is a UV disinfection system manufacturer who provides its customers with comprehensive support throughout the entire process, from setting requirements to the ongoing operational process. Our responsibility does not stop as soon as the system is sent.

Feel free to get in touch with us if you want more information about how we can help you.