ABOUT THE CLIENT

SALMON SMOLT RAS FACILITY IN NORWAY

Salmar Senja 1 & 2 is a land-based RAS facility located in Senja, Norway, with a total size of 25.500 m2. The site is designed to supply smolt to all the company’s sea sites in northern Norway, with the smolt being transferred by wellboat upon reaching a weight of 120 grams.

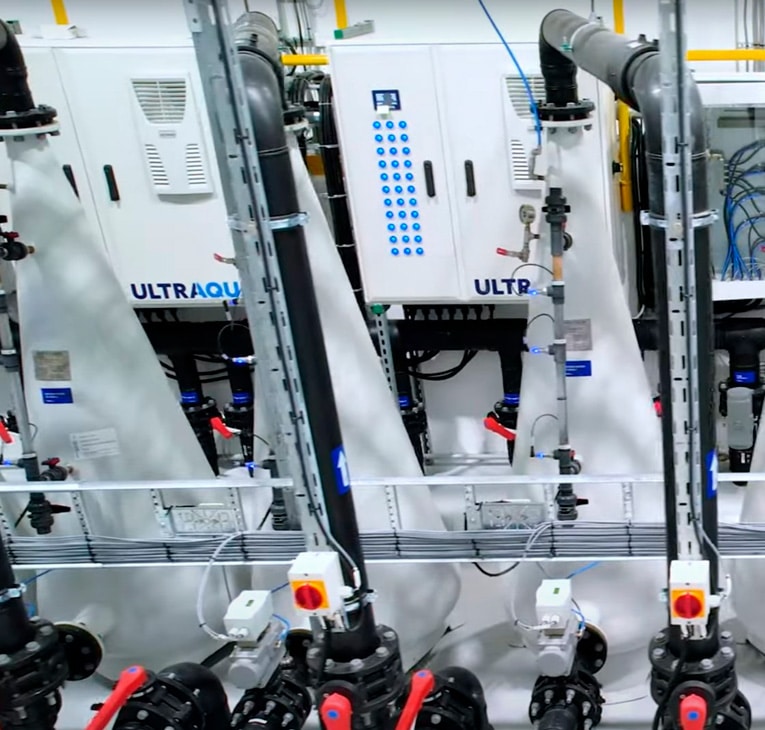

The site is built in two phases within five years of each other (2017: 12.000 m2 – 2023: 13.500 m2), with both facilities utilizing UV disinfection to maintain disinfected water for the Atlantic salmon to thrive. Combined, the facilities are able to produce a capacity of close to 29 million Atlantic salmon smolt of 120g per year.

WHAT THE CLIENT NEEDED

DISINFECTED WATER THROUGHOUT THE ENTIRE FACILITY

To accommodate such an ambitious facility of this scale, state-of-the-art disinfection technology was essential to accommodate the world-class post-smolt RAS facility. The combined capacity of close to 29 million Atlantic salmon smolt, with a feed capacity of 31.8 tons per day naturally sets huge requirements for disinfected water throughout the entire facility.

The strategic location of the facility means it can run on a combination of fresh water and brackish water derived directly from the surrounding water.