OPTIMIZED FOR MAXIMUM EFFICIENCY & A COMPACT FOOTPRINT

MARKET LEADING ENERGY EFFICIENCY

EASY MAINTENANCE AND INSTALLATION

EXCELLENT LEVEL OF CUSTOMIZATION

AVAILABLE IN SKID-MOUNTED CONFIGURATION

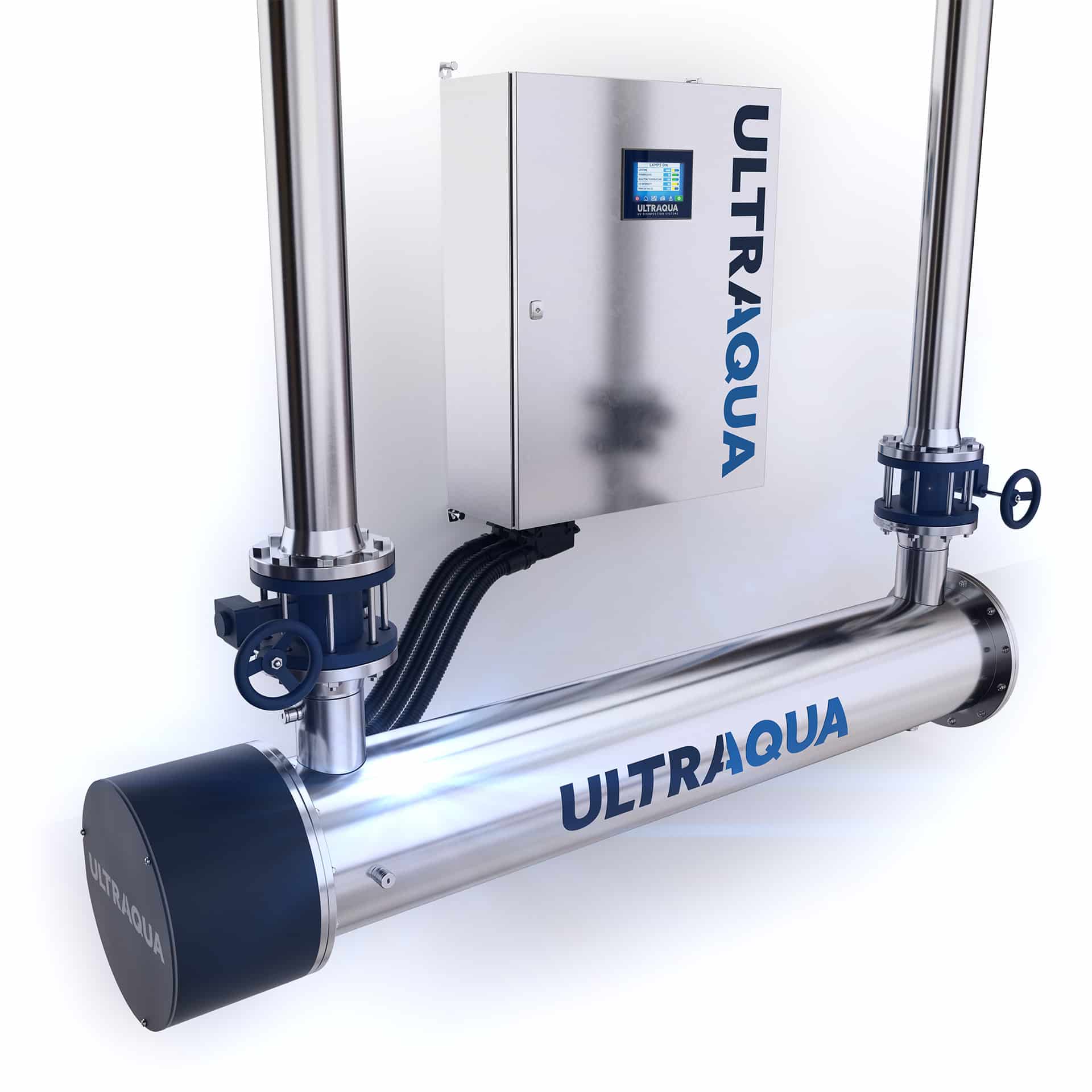

PRODUCT DESCRIPTION

ULTRATOX SERIES

Reducing Total Organic Carbon (TOC) is critical in applications such as semiconductors & microelectronics, pharmaceuticals, food and beverage & process wastewater where even the smallest contaminants can affect the quality of the products if the microorganisms are allowed to spread through the organic impurities.

The ULTRATOX series is developed specifically for TOC reduction excellence, featuring ULTRATOX VUV lamps which emit light at 185nm wavelength – light that has more energy than the 254nm used in standard UV water disinfection applications. This vacuum UV light energy promotes the formation of OH- radicals from the photolysis of water. The OH-radicals react with the organic matter in the water leading to the oxidation into CO2 (carbon dioxide) and H20 (water), resulting in the removal of TOC.

The ULTRATOX series has been optimized through a combined chemical process and CFD modeling approach. For additional improved efficiency, the system can be combined with the addition of other oxidants such as hydrogen peroxide and ozone.

KEY HIGHLIGHTS

- TOC levels reduced to < 1 ppb

- Modular skid design for higher flowrates – over 50% reduced footprint

- Guaranteed 12 000-hour ULTRATOX lamp lifetime

- High-grade electropolished stainless steel AISI 316L construction – Up to 30% energy savings with internal reflection

- Complete control with the customizable ULTRATOUCH control cabinets