About the project

PHARMACEUTICAL WATER RECOVERY & RECYCLING IN DENMARK

In this collaborative project, three industrial partners, ULTRAAQUA A/S, MipSalus ApS & Process Design A/S, supported by the independent consultancy company IN-Water ApS, teamed up to carry out a MUDP lighthouse project supported by the Danish Environmental Protection Agency. MUDP project grants are earmarked to projects that contribute with solutions to current environmental challenges.

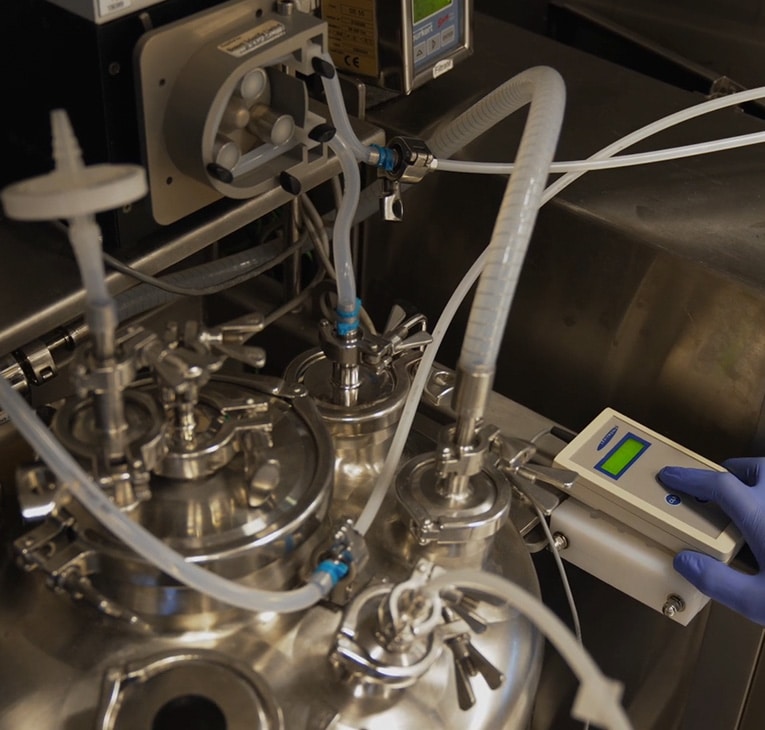

The project revolved around developing and establishing a facility for demonstration and documentation of technologies for circular economy and optimized resource recovery and recycling. This was carried out in relation to pharmaceutical production of a new Danish medical product called Phelimin.

Traditionally, the pharmaceutical industry has not prioritized environmental sustainability, as the urgency of time-to-market often overshadows the integration of green solutions in the development and production phases of new medicinal products. Once a product nears the market, it is challenging and complex to alter the validated and approved process, even if it is environmentally beneficial. To achieve environmental sustainability in the pharmaceutical industry, early incorporation of green solutions and “circular-by-design” principles are essential, particularly during the concept planning stages of process and production development.

WHAT THE CLIENT NEEDED

SUSTAINABLE WATER RECOVERY & RECYCLING

One of the primary environmental challenges in pharmaceutical production is the extensive use of water and organic solvents, which are typically not recycled. There is a need for solutions that can regenerate organic solvents, costly template molecules, buffers, and water to meet the original quality specifications set during regulatory review and approval.

If such solutions are incorporated at the design phase of the pharmaceutical production process development, and if adequate documentation is provided to convince regulatory authorities, it becomes possible to recycle organic solvents and water. This recycling can occur either to their point of origin in the production process or further upstream, significantly reducing their overall usage.

Particularly in the production of the Phelimin polymer, substantial consumption of synthesis oil, ethanol, template molecules, buffers, and pharmaceutical-quality water occurs. This project has dealt with reclaim and recovery solutions for this specifically.