Geosmin Removal in Recirculating Aquaculture Systems (RAS)

28 April 2021Through decades in the aquaculture industry, there has been a lack of solutions for problems relating to geosmin in RAS fish production. These problems lead to economic consequences for RAS facilities worldwide year after year.

Read further to explore the solution for Geosmin removal.

What is Geosmin and why is it a problem in RAS fish production?

Geosmin and Methyl-Isoborneol (MIB) are naturally occurring compounds that are commonly found in the fish production of RAS (Recirculating Aquaculture Systems). Both substances accumulate in the fat tissue of the fish which can lead to a muddy taste from the fish, which is not attractive for the buyers.

This ultimately leads to rejections of produce by the fish refining companies. Additionally, it creates the need to off-flavor the fish in purge tanks, which causes prolonged production times.

The Geosmin mitigation challenge

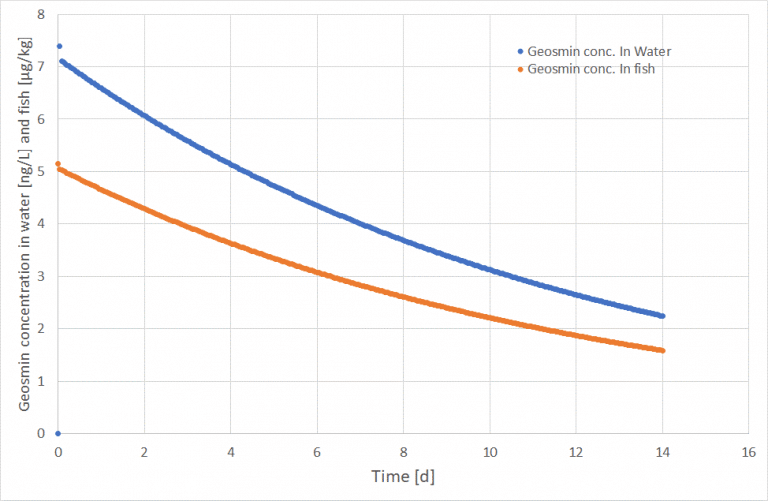

As of today, the usual method to remove geosmin from fish is by placing the fish into large high purity water tanks that are rich in oxygen. Doing so, the geosmin from their bodies get transferred to the water until it reaches equilibrium. Unfortunately, this is a relatively costly method to ensure proper removal, as large quantities of pure water are required. In addition to this, the purge process adds on average an extra 10 days of fish delivery time, required for the geosmin to be reduced to limits of 5ng/L.

This highlights the importance of a geosmin reduction solution, to avoid the prolonged sales cycle.

Research-based Geosmin assistance

The ULTRAAQUA research department has first-hand experience in solving and documenting geosmin control. The most optimal strategy concerning removing geosmin is to avoid or minimize the concentration of geosmin in the culture tanks, thus minimizing the need for off-flavoring in the purge tanks further on.

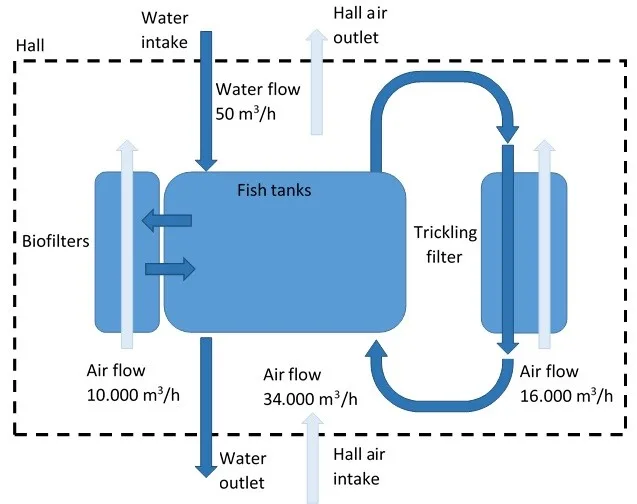

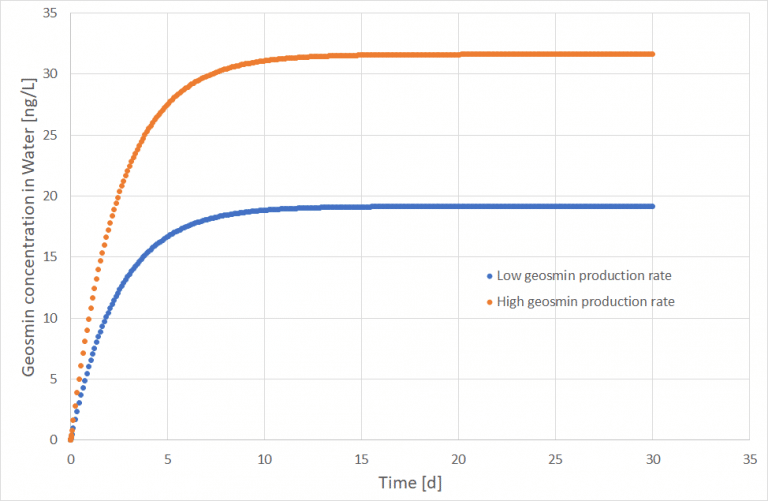

Our R&D engineers and chemists have developed quantification tools to model and predict geosmin formation rates in RAS systems. The results from these different scenarios can then be applied to determine the best possible geosmin mitigation strategy.

Solving the Geosmin issue

Our consultants are able to assist in optimizing the plant architecture and management strategies to reduce geosmin formation. Additionally, ULTRAAQUA offer equipment to remove accumulated geosmin.

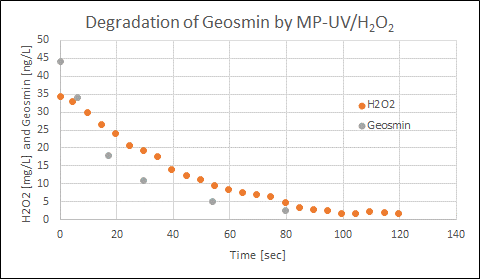

The optimal solution typically varies from site to site depending on local characteristics. The best possible solution usually involves ULTRAAQUA AOP systems for combined chemical oxidation and photolysis breakdown. It is important to note that each case is different due to varying RAS intenseness, different processes involved, and the variation in farm management, which makes each case require thorough investigation.

Get in touch with us through the contact formula below to learn more.