ABOUT THE CLIENT

SHRIMP FARM IN NIGERIA

Atlantic Shrimpers Ltd. was established in Lagos, Nigeria in 1996 and has grown into a successful global business. In 1996 the shrimp fishing fleet consisted of 16 vessels and currently, there are 72 vessels actively fishing for shrimp. In 2016 ASL opened a 160-hectare black tiger shrimp farm in Badagry just outside Lagos. This facility includes its own hatchery and processing plant, to be able to control the quality of the final product through its entire cycle. The total production capacity is 1,200 tons per annum. The farm including the hatchery and processing plant provides work to approximately 300-350 local people.

WHAT THE CLIENT NEEDED

HIGH FLOW RATE EXCELLENCE

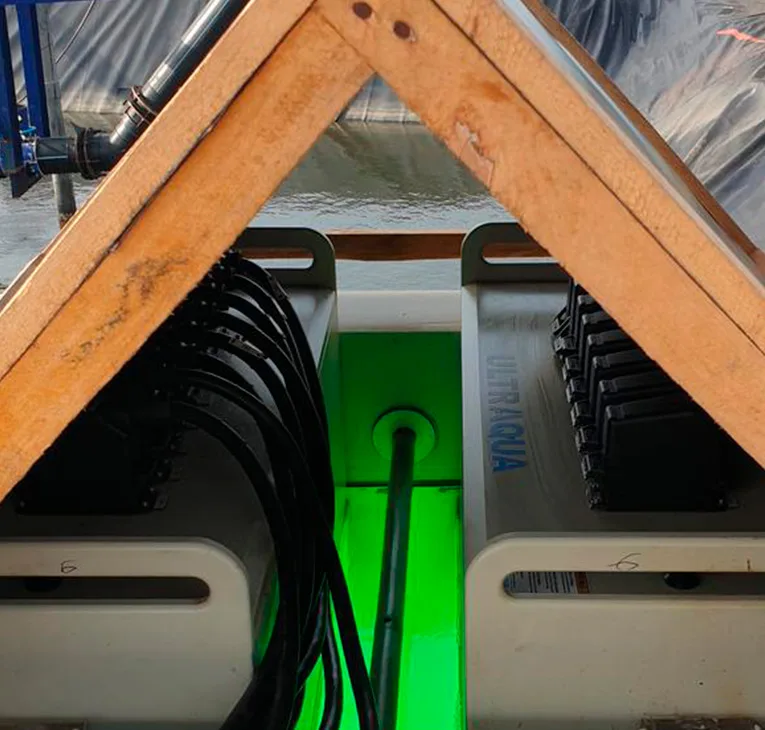

Atlantic Shrimpers Inc. chose to use UV technology as they are dealing with large volumes of water. In combination with large drum filters, it became possible to disinfect large quantities of water continuously. The method that was used to disinfect previously was chlorination, but besides the fact that this method is more expensive and not chemical-free, it also works in batches, reducing the availability of renewal water for the farm.

Another reason that UV was chosen is the low maintenance requirements, removing labor-intensive and complicated processes.