ABOUT THE CLIENT

RAS FACILITY IN GREECE

The Hellenic Centre for Marine Research (HCMR) is located in Greece and incorporates the research institute IMBBC (The Institute of Marine Biology, Biotechnology and Aquaculture). This research institute is considered to be one of the most important research institutes in Europe, having personnel of 133 people including 40 researchers, 40 active projects, and 1681 publications, with an annual 4.5 million Euros in research funding. The institute is backed by the R&D of scientists in Greece that the aquatic environment has developed over the last 20 years.

The HCMR-Aqualabs features a broodstock facility, that is dedicated to researching Fish Reproduction and Physiology, consisting of tanks of different volumes, equipped with temperature and photoperiod control for optimal breeding conditions. Currently, the broodstock tanks are operated on a flow-through system.

The wet and dry laboratories are facilitated with advanced technologies for fish sampling and initial evaluation of gamete and egg quality, and equipment with advanced microscopy techniques and computer-assisted sperm analysis (CASA) systems. The analytical laboratory supports research in reproductive biology and endocrinology, equipped with ELISAs for hormonal analyses, histological evaluation tools, temperature-controlled incubators, and spectrophotometers for water quality monitoring. Additionally, the laboratory produces polymer-based controlled-release devices for hormonal induction and enhancement of sperm production.

WHAT THE CLIENT NEEDED

UPGRADING FROM FLOW-THROUGH TO RAS

The main goal was to convert 2 Broodstock tanks (Sea Bream/Sea Bass) from a flow-through system to a Recirculating Aquaculture System (RAS).

The project is part of the Horizon Europe Framework Programme under the acronym “Cure4Aqua’’ work package 6 – Development of Detection tools and technology for improved aquaculture health and welfare. The purpose of the project is to research the optimization of non-invasive reproductive and stress hormone monitoring in gilthead sea bream broodstock to safeguard that water accumulation does not result in reproductive dysfunction.

Broodstock facilities are constantly under investigation for the development of fish strains with faster growth, adaptation to low fish-meal diets, increased disease resistance, and improved flesh quality. Selected broodstocks must be maintained in very high biosecurity facilities, to prevent their loss, and must be provided with the optimal conditions to reproduce efficiently and on demand.

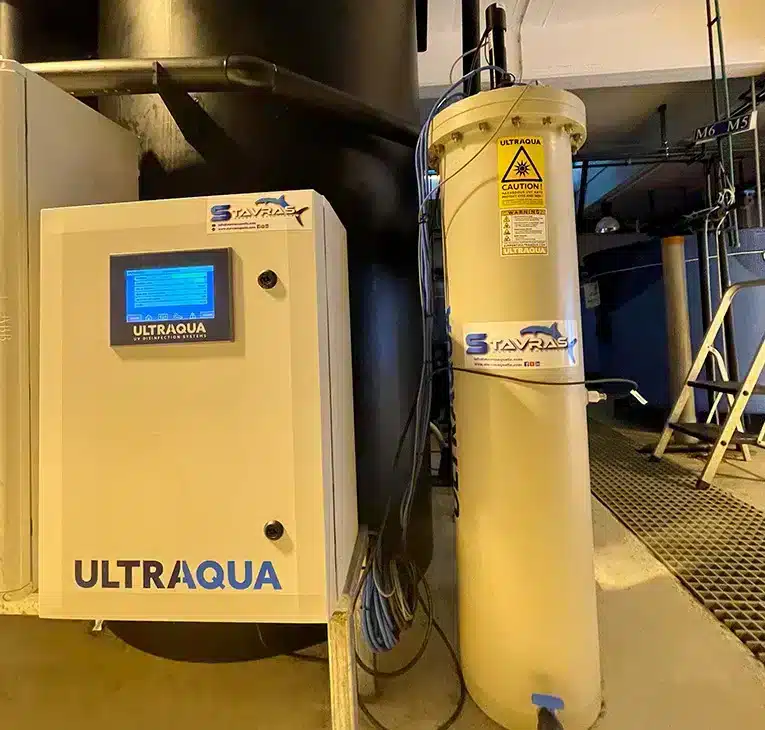

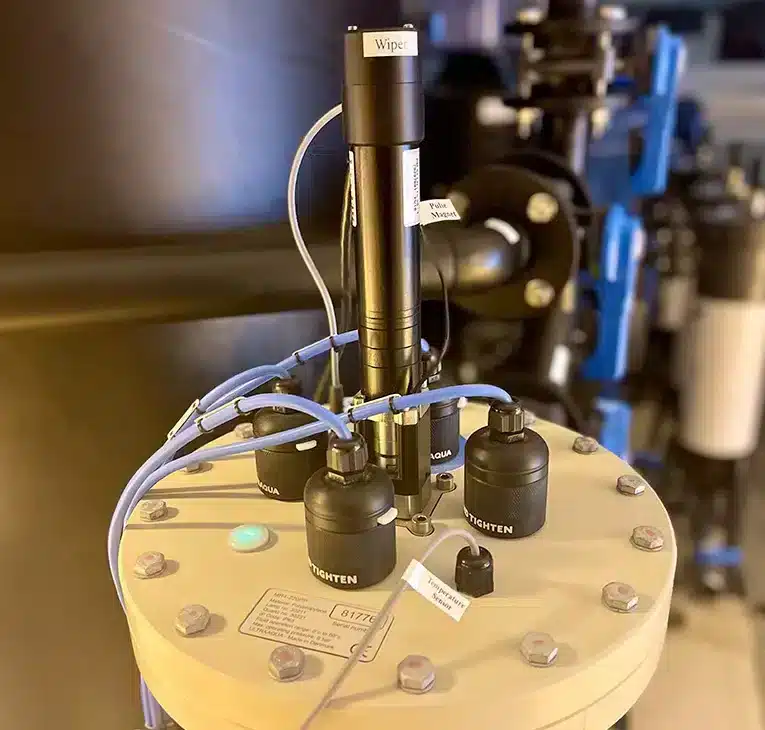

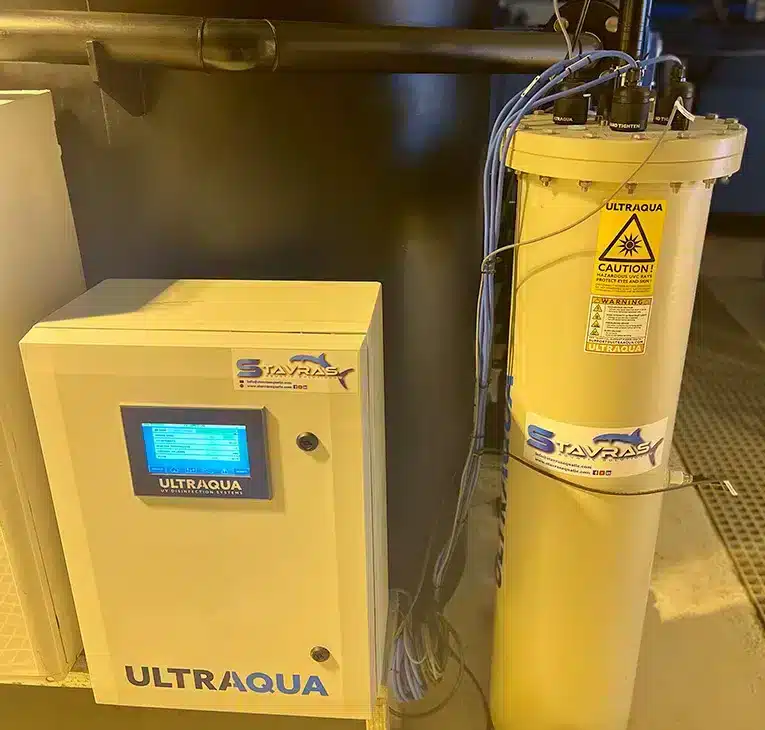

Absolute biosecurity in broodstock management is exclusively achieved by RAS systems where a small volume of new water is exchanged daily, while the entire volume of the system is filtered through a cascade of filters (mechanical, biological, CO2 stripping, UV disinfection, etc.) to ensure the fish are kept in a pathogen-free environment.