ABOUT THE CLIENT

POST-SMOLT RAS FACILITY IN NORWAY

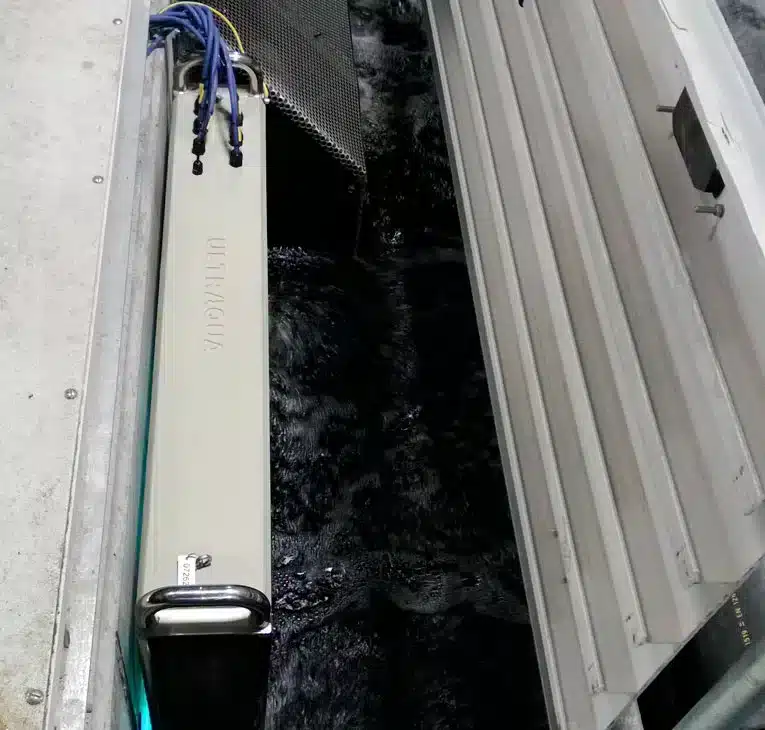

Located in Norway, one of the world’s biggest facilities of post-smolt production is found. The facility is owned by the Norwegian seafood pioneer Lerøy Seafood, which practices a major emphasis on sustainable practices throughout the entire company.

The innovative facility allows 98% of the water to be recirculated and re-used, highlighting the efficiency of salmon post-smolt production in Recirculating Aquaculture Systems.

WHAT THE CLIENT NEEDED

STATE-OF-THE-ART INTAKE WATER DISINFECTION

To accommodate such an ambitious facility of this scale, state-of-the-art disinfection technology was essential to establish a world-class post-smolt RAS facility.

This comes to light when looking into the facility setup, which consists of 14 fish tanks, with a planned production of 14 million big smolt divided in 5 rounds per year. The smolt is kept in these tanks in their early life stage from a weight of 80 grams to 700 grams, whereafter they are moved to the nearby sea until they are fully grown.