How Does a UV Disinfection System Work?

20 June 2023With an all-time high demand for cost-efficient and sustainable solutions to provide clean water, UV disinfection systems have taken on an increasingly important role. It is especially the global sustainability focus that has made choosing the right solution for water disinfection challenges ever more important. The growing environmental awareness combined with stricter regulations for effluent discharge standards continues to fill the agenda in this regard.

Since UV technology was discovered well over 100 years ago, it has undergone huge technological improvements, which today has made it impossible to ignore when it comes to water treatment processes.

UV systems are a globally accepted solution for water disinfection due to being a chemical-free sustainable solution, combined with being able of inactivating bacteria, viruses, and protozoa, which makes the technology vital for the future of water disinfection.

Let’s take a deeper look at how UV systems work.

Watch the video below for a full overview of the UV system disinfection process – or continue reading below.

How a UV disinfection system disinfects water

Disinfecting water with UV systems is a very straightforward, yet extremely efficient method to ensure disinfected water.

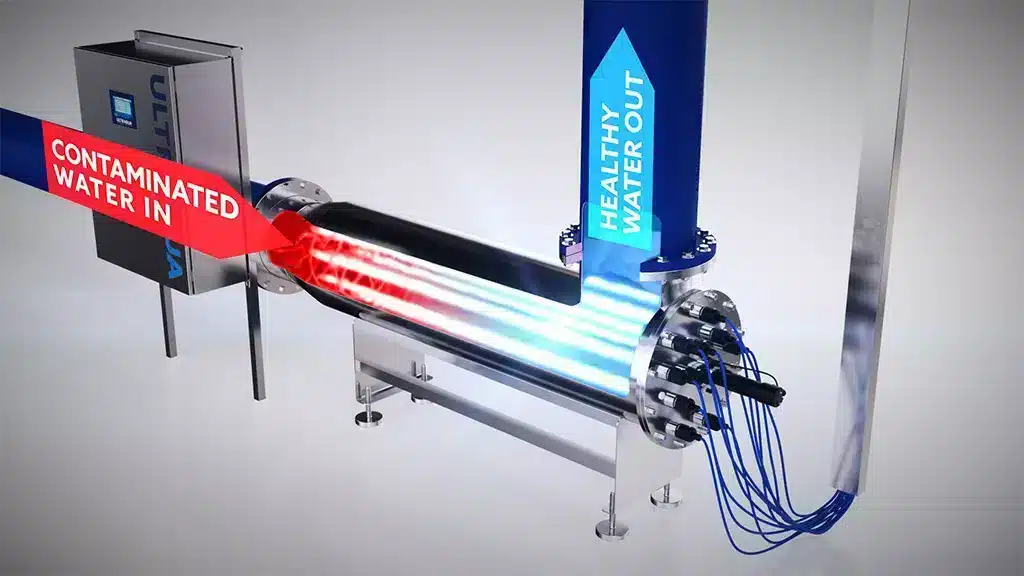

As seen on the image below, the water flows through the piping system and through the UV chamber. In this chamber, the water is exposed to ultraviolet light, that is emitted from the UV lamps. The UV light from the lamps has a specific wavelength in the UV-C spectrum (around 254nm), that enables microorganism inactivation if exposed with the right intensity.

In technical terms, when the water comes into contact with UV light, the chemical bonds are broken down, which changes the DNA structure. It is this change in the DNA structure that disables the pathogens’ ability to perform vital cellular functions, including reproducing or causing infection.

As the video above shows, bacteria such as E. coli reproduce extremely rapidly. This is where the UV lamps come into action to damage the DNA or RNA of the microorganisms, which disrupts their ability to function and replicate.

Make sure that the right UV system is selected

Dependent on the efficiency of the lamps and the microorganism to be inactivated – the contaminated water that has gone into the system will come out disinfected. This is why it is essential to make sure that the right UV system is selected for the specific water to be treated. In other words – If the UV system is too small for the task, it will not be able to inactivate the microorganisms, as the rays emitted from the lamps will not be powerful enough. All factors for ensuring proper water treatment conditions for the specific challenge are naturally assessed and considered when a UV system from ULTRAAQUA is inquired.

As a notable advantage, the disinfected water coming out of the reactor will have no altering of taste, odor, or color of the water. This means that both the physical and chemical properties of the water remain identical both before and after the treatment.

While there are averages for the different water treatment applications such as drinking water facilities, it is always considered to be best practice to test and measure the water before selecting the UV system to make sure the targeted microorganisms are inactivated.

The benefits of using UV systems

Even though water can visually appear to be clean, there is no guarantee that it does not contain significant levels of harmful bacteria, viruses, and parasites. UV disinfection has a vital role in many water treatment processes worldwide to solve this biosecurity issue. While UV disinfection can not always stand alone in water treatment processes, there are several benefits of including the technology.

This includes benefits such as:

- A lower carbon footprint in comparison to alternative disinfection methods

- Low maintenance, administration, and OPEX costs

- No dangerous chemicals involved (storage, handling, and residuals)

- No by-products being created in the disinfection process

- No change in the water properties such as pH and temperature

- Instant treatment with no processing time

- Simple and safe implementation

It is especially a beneficial alternative to chlorine disinfection, which can potentially result in health complications such as respiratory diseases, as well as being incapable of inactivating Cryptosporidium and Giardia.

What components are a UV disinfection system made of?

Understanding the components included in a common UV disinfection system can be beneficial in regard to getting a full understanding of how UV systems work. Each of these parts has an important role to carry out in the disinfection process.

- UV lamps

The UV lamps are the heart of the UV system, which emits UV-C ultraviolet light to inactivate the microorganisms. With enough UV light exposure, microorganism inactivation will be achieved. Dependent on the water treatment challenge, either low-pressure or medium-pressure lamps can be used.

- Quartz Sleeves

The quartz sleeves allow the UV lamps to do their job by protecting the lamp from water. To prevent fouling over time, quartz sleeve wiping can be integrated to consistently keep the quartz sleeves clean, allowing the UV lamps to stay close to full performance.

- Reactor

The reactor is where the UV disinfection process takes place. As the water flows through the chamber, the UV lamps are doing their job to inactivate the microorganisms. Dependent on the water treatment challenge, the reactor material can consist of either stainless steel (SS), polypropylene (PP), or high-density polyethylene (PEHD).

- Ballast

The ballasts ensure that the system is provided with the accurate electrical input it needs to maintain a stable operation.

- Control Cabinet

The control cabinet is what controls the disinfection behind the scenes, by offering the operator control over the state of the system. Besides advanced functions, it is usually capable of sending out alerts if the lamps are not working correctly and providing info about the disinfection performance.

All these main components are a necessity for any operational UV disinfection system. The amount of them will however vary dependent on the disinfection challenge, where specific cases might require more lamps than others. For one closed vessel reactor, the UV systems from ULTRAAQUA can range from 1 lamp up to 56 UV lamps per unit.

If you are interested in learning more about our UV disinfection systems, you are always welcome to reach out to our sales engineers at sales@ultraaqua.com – or use the contact formula below.