The Benefits of Advanced Oxidation Processes (AOP) for Water Treatment

24 March 2025The global water crisis is intensifying due to the combined effects of environmental pollution and climate change.

This growing demand for safe and reliable water resources, combined with diminishing surface and groundwater availability, puts immense pressure on water supply systems and quality standards.

Meanwhile, the increasing presence of persistent man-made chemicals and micropollutants in water sources poses significant risks to both human health and aquatic ecosystems, creating a complex challenge for water treatment facilities worldwide.

Advanced Oxidation Processes (AOPs) offer a powerful and sustainable solution to these issues, as these methods are capable of breaking down even the most persistent contaminants.

The proven effectiveness and cost-efficiency of AOP solutions have led to implementation in water treatment facilities around the globe. From municipal wastewater recycling to surface and groundwater treatment, AOP offers reliable and efficient water treatment across a wide range of applications.

Water treatment technology combinations for advanced oxidation processes (AOP)

Advanced Oxidation Processes (AOP) is a common name for the chemical/photochemical reactions that generate OH-radicals in the water, with the purpose of degrading persistent and toxic chemical compounds.

Typical examples of AOP combinations are:

- Vacuum-UV / Ozone

- UV / Hydrogen Peroxide

- UV / Persulfate

- UV / Chlorine

- Ozone/Peroxide

- Vacuum-UV

AOP is frequently employed as a final polishing step in many water treatment applications, to provide combined disinfection and removal of trace organic compounds to very low levels, thus ensuring water of very high purity.

UV/Peroxide

The fundamental principle of this AOP is that hydrogen peroxide absorbs UV-light to varying degrees in the whole range from 200-300nm and this leads to homolytic photolysis of hydrogen peroxide into hydroxyl radicals for contaminant degradation. This process is preferred over the UV/Chlorine process when the pH of the water is in the slightly acidic to neutral range. The selection of UV-lamp type for this process depends on water characteristics.

UV/Persulfate

The UV/Persulfate AOP utilizes UV irradiation to activate persulfate generating sulfate radicals with strong oxidation potential for contaminant degradation. Unlike hydroxyl radicals, sulfate radicals are more selective and effective against electron-deficient contaminants and have specific advantages in treating nitrogen-containing compounds i.e. urea. The process is most efficient at acidic to neutral pH (pH 5–7), as alkaline conditions promote radical conversion to weaker radical species. This process typically uses low-pressure UV-lamp technology.

UV/Chlorine

The UV/Chlorine AOP uses UV irradiation to photolyze chlorine species that absorbs UV-light to varying degree in the whole range from 200-300nm, generating hydroxyl and chlorine radicals for contaminant degradation. It is most effective when the pH of the water is in the neutral to slightly alkaline range, where chlorine radicals enhance oxidation selectivity. The selection of UV-lamp type for this process is dependent on water characteristics.

Ozone/Peroxide

The Ozone/Peroxide AOP enhances conventional ozone oxidation by adding hydrogen peroxide, which accelerates ozone decomposition into hydroxyl radicals. Optimal performance occurs at neutral to slightly alkaline pH, where hydroxyl radical production is maximized. This process is typically chosen for waters where the UV-transmission is low and the UV-based AOPs are less feasible.

Vacuum-UV

The Vacuum-UV (VUV) AOP utilizes high-energy 185 nm UV light to directly photolyze water molecules, generating hydroxyl radicals without chemical additives. This process enables broad-spectrum oxidation of organic contaminants, making it highly effective in TOC removal in ultrapure water production. While it eliminates the need for external oxidants, its high energy consumption and limited VUV-light penetration depth require optimized reactor designs for large-scale applications.

Ozone/Vacuum-UV

This combination is applied to enhance the performance of the VUV-AOP. Ozone is dosed prior to the Vacuum-UV reactor to selectively oxidize background dissolved organic matter to products with lower reactivity towards OH-radicals ensuring less competition for OH radicals and more efficient compound removal in the subsequent VUV-AOP.

AOP implemented at a Danish Carlsberg brewery

As part of DRIP (Danish Partnership for Resource and Water-Efficient Industrial Food Production), ULTRAAQUA has been involved in creating the future of beer breweries, through the utilization of AOP (Advanced Oxidation Process) systems.

Implementing AOP water treatment at the Carlsberg facility in Fredericia has allowed Carlsberg to re-use 90% of its process water and save 10% more energy, cutting the total water use in half – from 2.9 hl of water to 1.4 hl of water per hl of beer.

Employing AOP processes has become an increasingly favored solution due to its effectiveness in applications that require a high level of security and sanitation.

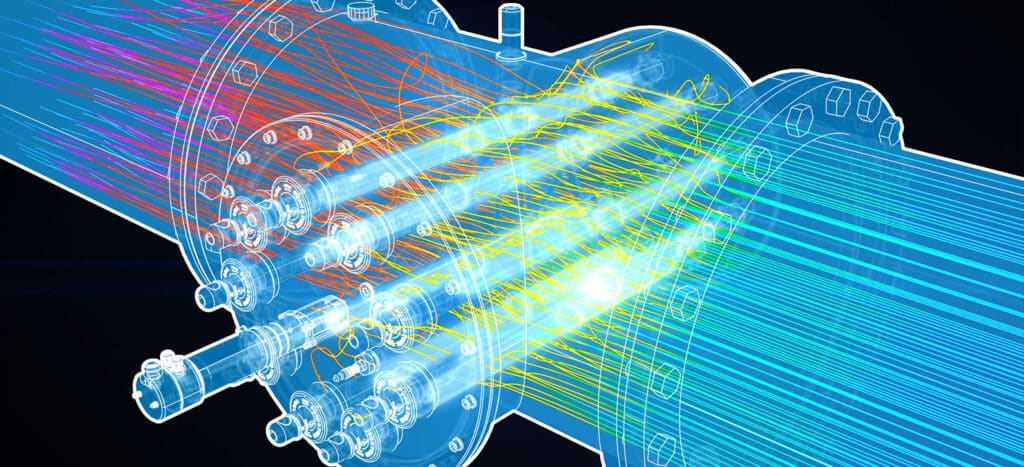

More specifically, comprehensive laboratory experiments were conducted and combined with advanced integrated CFD modeling to design a UV-based AOP reactor, stabilizing chemical and microbiological water quality, and delaying aftergrowth potential during storage before reuse. AOP acts as the last treatment step of the entire plant before being able to reuse the water.

The initiative has made Carlsberg’s Fredericia brewery the first in the world to nearly eliminate water waste, placing Carlsberg above its 2030 sustainability targets.

Getting started with AOP water treatment

The ULTRAAQUA R&D department conducts, supports, and pioneers some of the latest developmental work within the water industry.

The projects are primarily focused on developing unique and advanced solutions to solve some of the world’s most complex water quality problems.

The vast number of resources allocated for these R&D activities including numerous AOP-based projects has resulted in a comprehensive knowledge of the optimal AOP setup for even the most complex challenges.

The comprehensive in-house laboratory and testing areas facilitate optimal conditions for carrying out AOP projects, with the ability to simulate full-scale pilot trials. This allows precise evaluation of system performance, to ensure that the selected solution is cost-effective and tailored to the challenge at hand.

Extensive testing and pre-evaluation before selecting the ideal solution effectively minimize risk and ensure long-term cost-efficiency.

ULTRAAQUA provides customized AOP solutions to accommodate virtually any water treatment challenge, using advanced integrated CFD, UV fluence field, and radical chemistry process models with the purpose of calculating and optimizing the space-dependent OH-radical concentration and prediction of the target compound degradation.

The result is a selection of reaction system, lamp type, and optimal reactor design that ensures an efficient treatment process, taking into account the physicochemical characteristics of the water matrix and target compounds. With highly complex water matrices, empirical target compound degradation can be obtained experimentally in ULTRAAQUA’s high-quality research laboratory.

If you need personal guidance for your specific AOP water treatment challenge, feel free to reach out to us anytime by contacting our sales engineers at sales@ultraaqua.com – or by using the contact formula below. We are able to assist from the very first water sample analysis to a full-scale solution.