ABOUT THE CLIENT

TROUT RAS FACILITY IN CANADA

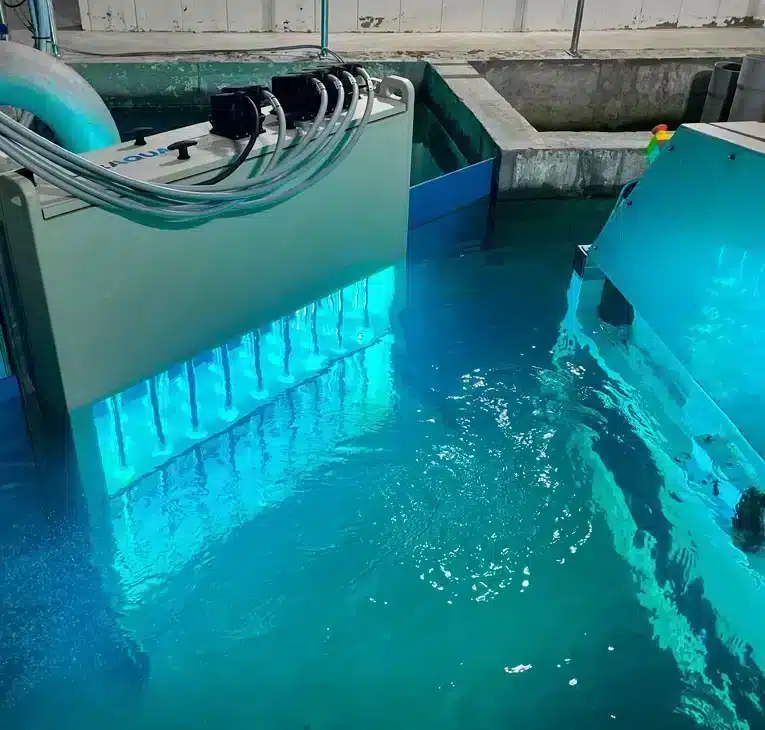

Located in Québec, Canada, the Bobines fish farm operates a land-based rainbow trout breeding and processing site. The fish farm has an exceptional focus on sustainability, having implemented best practices for RAS facilities to optimize the production yield while protecting the environment.

The RAS utilizes over 90% water recirculation, which means that less than 10% of the used water comes directly from the groundwater. The farm uses high-quality spring water from the groundwater, which is protected from any external contamination. The cool and constant temperature throughout the year facilitates excellent conditions for the breeding of fish which contributes to their well-being by replicating the natural environment of the fish.

As part of an ambitious expansion plan, the farm has built a new comprehensive RAS facility in 2021.

WHAT THE CLIENT NEEDED

SUSTAINABLE DISINFECTION

The client needed a solution to accommodate the defined requirements of their new hatchery design as part of the comprehensive expansion.

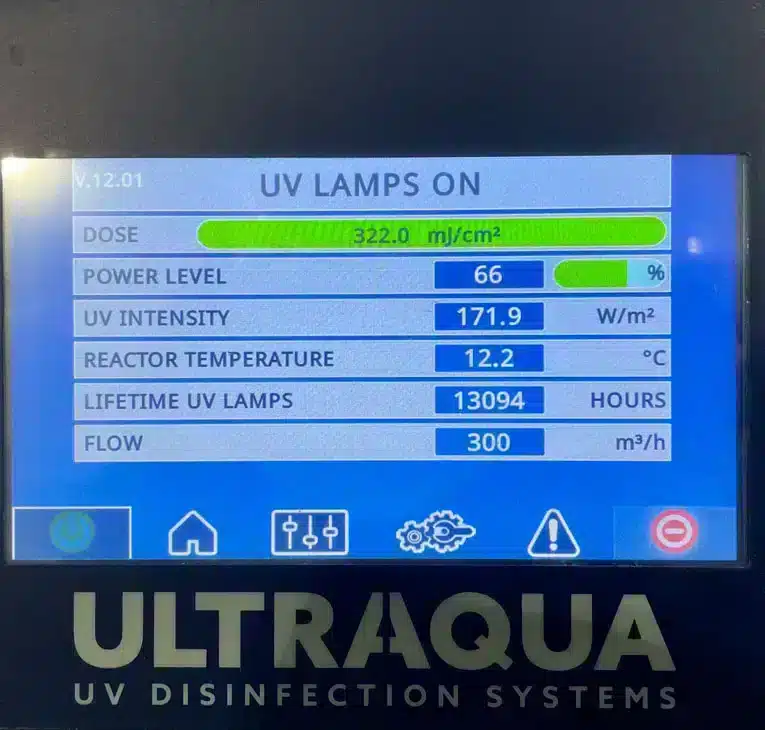

The hatchery design includes 46 fish tanks, 98%+ recirculation rate, 450 m3/h flow recirculation and a capacity of 1 million fry per year.

To accommodate these requirements, it was evident that utilizing UV systems would be a great match, due to the numerous advantages when utilized for complex RAS systems. This includes complete water biosecurity control, water quality management, as well as being completely chemical-free. UV systems are a vital integration of a well-functioning and cost-efficient RAS facility, as they are able of ensuring comprehensive water biosecurity by reducing virus or bacteria outbreaks.